-

Recent Posts

Archives

- January 2024

- December 2023

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- February 2019

- January 2019

- December 2018

- October 2018

- September 2018

- August 2018

- June 2018

- May 2018

- April 2018

- January 2018

- November 2017

- October 2017

- September 2017

- August 2017

- July 2017

- May 2017

- April 2017

- March 2017

- February 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- July 2016

- May 2016

- April 2016

- March 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- May 2015

- April 2015

- March 2015

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- April 2013

- March 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

Ishikawa Prefecture Earthquake

Prayers for all in Ishikawa, hit so hard by a massive earthquake on New Year’s Day.

Prayers for all in Ishikawa, hit so hard by a massive earthquake on New Year’s Day.

While the loss of life was not as high as it might have been, in the hardest hit area, the city of Suzu on the Noto Peninsula, 90% of all the buildings were flattened. There are about 33 sake breweries in Ishikawa Prefecture, and of the 12 in that hardest hit Suzu area, four were completely destroyed, all but two took on massive damage. Furthermore, the aftershocks are not finished, and some of them are quite strong. It will call for great support on many levels if they are to recover. Please be on the lookout for ways to provide that support, in any one of a number of ways, including financially.

I will post more information about ways to give, as well as other relevant info, as it becomes available.

“Seimai-buai“: A Tale Of Grossly Misplaced Importance

This post is a sample from Issue #37 of Sake Industry News. Each issue of SIN has a handful of current news stories and reports, and one technical article written by John Gauntner. It is published on the 1st and the 15th of each month, and includes an audio version of the content as well. A one-year subscription is US$100, or US$10 a month. Subscribe with no risk, since your first two issues are free, and you can cancel with no obligation. Learn more and subscribe here.

written by John Gauntner. It is published on the 1st and the 15th of each month, and includes an audio version of the content as well. A one-year subscription is US$100, or US$10 a month. Subscribe with no risk, since your first two issues are free, and you can cancel with no obligation. Learn more and subscribe here.

I recall a picture I recently saw of a wedding celebration. The couple was involved in the sake business somewhere outside of Japan, and clearly had access to a wide range of good sake. A dozen or so large bottles sat in an approachably haphazard arrangement in a basket so that the guests could access any of them easily. While the labels were all intact, each bottle had the seimai-buai (rice milling) written in inordinately large, colorful characters on the outside of the bottle. The message was clear, if perhaps a bit misguided: “this is all you need to know about this sake.”

I recall a picture I recently saw of a wedding celebration. The couple was involved in the sake business somewhere outside of Japan, and clearly had access to a wide range of good sake. A dozen or so large bottles sat in an approachably haphazard arrangement in a basket so that the guests could access any of them easily. While the labels were all intact, each bottle had the seimai-buai (rice milling) written in inordinately large, colorful characters on the outside of the bottle. The message was clear, if perhaps a bit misguided: “this is all you need to know about this sake.”

With that opening, let’s state up front the premise of this diatribe: Many people pay far too much attention to the seimai-buai. That includes consumers as well as those in distribution, both in and outside of Japan. And it includes myself from time to time, if I am not vigilant. For some people, it’s the first thing they want to know, and the last they consider.

In truth, though, it does not warrant that much attention! So I am suggesting we relegate it to secondary importance – at best. I am not suggesting that we should not look for it, or ignore it, but merely that we should not excessively focus on the seimai-buai number, or use it in choosing or assessing a sake; that’s all.

As a quick, concise review, the seimai-buai is the milling rate, and tells us how much of the outside of the rice grains were milled away before brewing. The number represents what remains after milling, rather than what was milled away. The eight grades of premium sake have legally defined minimum seimai-buai, and the number must be printed on the label for those grades, collectively known as tokutei-meishōshu, or “special designation sake”. (You can see those rules here ). If it is not listed on the label, the sake is a futsu-shu by default, i.e. not of a “special designation.” Which is fine.

So if you know the grades and take a few moments to remember what the seimai-buai is for each of them, by just seeing the grade you know about what the seimai would be,

The problem originated when some brewers began to make daiginjo with extremely highly milled rice, trying to outdo each other. Milling only to 50% is legally enough for a daiginjo, but sake milled to 35% are common. But some then pushed that, through 30 and 23, down to 18, 17, 8, 7, and even one percent. Then the curtain was closed on that game when one brewer hit zero percent (read about that here).

But this has left many with the idea that more milling is better, or at least more extravagant. In truth, most say that going beyond 40 percent is fairly meaningless in that the sake will not be intrinsically better just because of more milling. But still, the seimai-buai garners a lot of attention, and many folks like to be seen drinking – or talk about having tasted – sake with a very high seimai-buai (which is represented by a low number!).

It is not that anything is wrong with such sake. It’s great, for sure. Light, delicate, refined and aromatic. But such sake is but one type of sake, just one style, and while such milling and the requisite care in brewing necessitate a higher price, the sake itself is but one facet of the jewel that sake is, and is not better just because of the high milling.

Sure, we all like the rare, the special and the unique, myself again included. And if that is the figure of merit of the moment, then without a doubt such sake are the perfect choice. But for most people, most of the time, there is so much more to which to pay attention in a sake.

And again, this is not limited to people overseas, or even consumers. Many brewers in Japan find to their dismay that distributors preconceive a connection between the seimai-buai and the price they are willing to pay. And, as covered in way back in SIN #1, a few producers are choosing not to play the game, and confidently just leaving their sake graded as futsu-shu.

The main gist of what I am encouraging is to focus on it less. I am not suggesting we ignore the seimai-buai, or that it is uninteresting or not important, but merely that we should not focus on it above and beyond any one of another fifty factors, like rice variety, region, yeast, tōji and kura style, production method, maturity, temperature, food, climate – just to name a few.

In fact, from about 70 percent down to about 40 percent, it can tell us a lot about how heavy and rich or light and delicate a sake might be. It is only one factor contributing to that, but it is an admittedly important one.

The Murky Doburoku Illusion

This post is a sample from Issue #57 of Sake Industry News. Each issue of SIN has a handful of current news stories and reports, and one technical article written by John Gauntner. It is published on the 1st and the 15th of each month, and includes an audio version of the content as well. A one-year subscription is US$100, or US$10 a month. Subscribe with no risk, since your first two issues are free, and you can cancel with no obligation. Learn more and subscribe here.

This post is a sample from Issue #57 of Sake Industry News. Each issue of SIN has a handful of current news stories and reports, and one technical article written by John Gauntner. It is published on the 1st and the 15th of each month, and includes an audio version of the content as well. A one-year subscription is US$100, or US$10 a month. Subscribe with no risk, since your first two issues are free, and you can cancel with no obligation. Learn more and subscribe here.

In most issues of Sake Industry News, this column is used for slightly deep dives into technical aspects of sake, and once in a while for observations on trends or industry developments. Once in a while, though, I feel impelled to call out something that does not seem like it will lead anywhere, and does not look like it will be around in a few years, yet still gets lots of hype. One of those is doburoku.

What is it? First and foremost, doburoku is not a legally defined term. It refers to sake that is basically moonshine, in that it is fermented but the rice solids are not filtered out afterward. Sometimes it has a good dollop of carbon dioxide left in it as well. Long ago it is what people in the countryside made and drank for a buzz. But it was made illegal in the Meiji period because the government wanted to be able to visibly confirm if sake had been made by a proper brewery, and taxes therefore paid. So they changed the laws so that all sake had to have the rice solids filtered away first to be seishu, or legal sake.

Many consider and call nigori-zake “unfiltered,” but in fact it is filtered, just more coarsely to allow some rice solids through to the final product. Alternatively, they can add it back in, but however they do it, it is not unfiltered.

So doburoku can be totally unfiltered, although it does not have to be so. But basically, it is like moromi, i.e . fermented mash without filtering. And for some reason around which I cannot get my head, it appears to be growing in popularity. But I dunno… I cannot see this boom lasting.

. fermented mash without filtering. And for some reason around which I cannot get my head, it appears to be growing in popularity. But I dunno… I cannot see this boom lasting.

In truth, and I admit I am tempering my diction a bit, there is nothing much at all refined about it, and I am having trouble seeing much of an appeal. On top of being rough and unhewn, often the government makes producers flavor it with hops or something else so as to be sure non one confuses it with legally proper sake.

While flavored doburoku can be enjoyable, I cannot see how something so niche could ever grow into a significant sector, or even a worthwhile revenue stream for any enterprise. I wouldn’t even call it a flash in the pan, since there is not much of a flash to begin with.

Currently, there are a handful of sake brewers that are making doburoku, but most interesting among them are two or three that have received actual brewing licenses for the zasshu alcohol classification, under which what we know as doburoku would be legally classified. The National Tax Administration is notoriously against giving out any new seishu (proper sake) brewing licenses, as it does not make sense when the remaining 1150 or so are struggling to survive. But a zasshu brewing license? Yeah, sure, we’ll give you one of those. Just fill out this form…

But why would a sake brewery bother to get a license and build a facility just for something that seems destined to fall by the wayside?

Well, first of all, that part is only my opinion. Others may share it, but it is by no means a foregone conclusion of any doburoku business venture. But beyond that, I think there is another reason that brewers might start specialist breweries like those for doburoku, umeshu (plum sake) and more.

What might that be? In short, backdoor sake brewing licenses. In other words, I think they are betting that the NTA powers-that-be will watch them, and if they can prove they can develop, run and maintain a successful and profitable business making just doburoku et al, then in time, the NTA will eventually say, “Ok, you have proven yourself, you will likely be successful with proper sake too, we will grant you that brewing license.”

In fact, there has been at least one case of which I know, but surely there are others, in which this has in fact happened. Sure, I have heard rumors too, but even more convincing to me is that I cannot see any other reason for entering into the doburoku market, especially investing in a new facility. This is particularly true when once considers the people actually doing this; they all seem quite accomplished and intelligent. So they must have an endgame, and it ain’t doburoku; I am fairly sure about that.

But of course, no one can come out and say this. Those starting such production facilities cannot come out and say, “our plan is to get a sake license in ten years,” nor can the NTA say, “prove your mettle with doburoku, and then we can talk about seishu.” But that goal, however unspoken, seems quite palpable to me. And it has been corroborated by rumors from time to time as well. But once it happens, once there is a precedent, then the floodgates might open and other breweries may try to follow suit

Might I be wrong, and totally off base? Sure I might; that happens all the time. And whether or not I am incorrect is of no consequence to the cosmos.

Regardless, in all sincerity I do think that doburoku is a niche product and do not have serious expectations that it will go anywhere. It will likely remain not much more than a curiosity, in and of itself.

But what it will do is continue to draw much-needed positive attention to sake. So in spite of my reticence, I want to support the movement as much as can. And so, for the time being anyway, kampai with doburoku too, once in a while.

Hokkaido Rising

This article was originally published in Sake Industry News Issue #17

There are 47 prefectures in Japan, and every single one of them makes at least a little bit of sake. This was not the case until a few years ago, when one company in Kagoshima, the erstwhile lone holdout owing to its status as the premier sweet potato shochu producing region, added a sake to their array of shochu. Even in tropical Okinawa, the home of the idiosyncratic distillate awamori, there is one company who makes a tank or two of sake a year.

There are 47 prefectures in Japan, and every single one of them makes at least a little bit of sake. This was not the case until a few years ago, when one company in Kagoshima, the erstwhile lone holdout owing to its status as the premier sweet potato shochu producing region, added a sake to their array of shochu. Even in tropical Okinawa, the home of the idiosyncratic distillate awamori, there is one company who makes a tank or two of sake a year.

There are of course the major producing regions, like Hyogo, Kyoto, Niigata and Akita, and also those on the other end of the spectrum that produce very little. Buried in there somewhere amidst the more nondescript regions is Hokkaido. As the northernmost of Japan’s four main islands, Hokkaido is one prefecture all by its large self. But Hokkaido’s sake-brewing fortunes are possibly pivoting toward recognition and popularity.

The prefecture is attracting a lot of attention on several fronts that straddle a variety of industries. Namely, there are a couple of new breweries there on the sake production front; there are a handful of new sake rice varieties there showing up the agriculture front; and there is a lot of proactive tourism promotion there as well that continues to be a formidable destination draw. The intersecting aspects of these three are laden with potential as well.

Looking back a bit, Hokkaido once had over fifty breweries at its peak, and was the tenth largest brewing region. Things contracted from that zenith, and now there are only 13 breweries remaining, although many of them are noteworthy and appealing.

Next, let us look at sake rice. I recall a brewer from one of the Hokkaido companies once telling me that he found an old brochure from his own company on the floor of the storage room in the brewery. In the brochure, the company boasted – not stated, mind you, but actually boasted – that all of their rice was from Japan’s main island, Honshu, and that none was from Hokkaido.

Next, let us look at sake rice. I recall a brewer from one of the Hokkaido companies once telling me that he found an old brochure from his own company on the floor of the storage room in the brewery. In the brochure, the company boasted – not stated, mind you, but actually boasted – that all of their rice was from Japan’s main island, Honshu, and that none was from Hokkaido.

Why? Because back then, Hokkaido rice had a pretty bad reputation. But a combination of agriculture technology and, unfortunate though it may be, climate change has made Hokkaido rice quite appealing, tasty and reasonably priced.

On top of regular table rice, much effort has been put into developing sake rice strains too, with good success. Hokkaido represents about 22 percent of Japan’s topography, so there is plenty of room for sake rice cultivation. And rising to that challenge, Hokkaido is now the second largest rice-producing prefecture (for all rice, of course, not just sake rice).

There are three main sake rice varieties developed and grown in Hokkaido, all created in the last twenty years or so. The most widely grown, Ginpu, tends to yield light and clean sake (Ginpu, by the way, has established itself well enough to be used by breweries all over Japan, and is now firmly ensconced in the list of the ten most-grown sake rice varieties). Next is Suisei, which is well rounded and often yields a gentle sweetness that seems especially prominent amongst Hokkaido’s dry sake environment. And third is Kitashizuku, the newest. So new, in fact, that it is hard to see a tendency of character in the sake made using it. That will take another few years. There are a also a couple of widely grown table rice types used in sake brewing too, namely Kirara 397 and Yumepirika.

grown, Ginpu, tends to yield light and clean sake (Ginpu, by the way, has established itself well enough to be used by breweries all over Japan, and is now firmly ensconced in the list of the ten most-grown sake rice varieties). Next is Suisei, which is well rounded and often yields a gentle sweetness that seems especially prominent amongst Hokkaido’s dry sake environment. And third is Kitashizuku, the newest. So new, in fact, that it is hard to see a tendency of character in the sake made using it. That will take another few years. There are a also a couple of widely grown table rice types used in sake brewing too, namely Kirara 397 and Yumepirika.

There are, in fact, several breweries that look at global warming and believe that, as things get warmer, Hokkaido will become an increasingly important rice region, and as such it is beneficial to learn to use the rice from that region well, and to develop the personal relationships that will help ensure a steady supply once that time comes.

Back to the sakagura of Hokkaido, several are well-known and have been for decades, perhaps none more than Otokoyama. Others include, Kokushi Muso, Chitosetsuru, and Kunimare. Lately, a smaller brewery making a sake called Niseko is making its mark as well.

Perhaps most interesting to many in the sake world are two others, one being Kawakami Taisetsu. Readers may recall that in the last issue of Sake Industry News we spoke of the hassles involved with getting a sake-brewing license, and in this case as well it was not granted anew. Rather, a passionate investor of some means bought a dormant brewery in Mie Prefecture in the western part of Japan and moved the company up to Kawakami Village in Hokkaido and started the company anew.

The tōji is a journeyman master brewer, having worked at breweries in five different prefectures before his most recent one in Hokkaido, which went under a couple years ago. The two teamed up and began brewing Kawakami Taisetsu in a small, craft-laden manner using the three aforementioned Hokkaido sake rice types. As mentioned above in Industry Stirrings, things have gone well enough for them that they are opening a second brewing location that doubles as a tourism site and is to some degree open to the public.

There is also one more brewery that packed everything up and moved up to Hokkaido: Michizakura Shuzō, brewers of Michizakura sake. This company moved their production to a village in Hokkaido that had no breweries. The brewery itself is under construction, with brewing slated to begin in October. There is a story as to how and why this move took place, but I am not yet privy to it. Look for that in a future issue.

Then there is the touristic aspect of Hokkaido. It has long been a popular ski destination, although perhaps more for visitors to Japan than Japanese people. But beyond that there are just huge, beautiful expanses of nature, with hiking and camping and a plethora of agricultural products to enjoy. All of these are great opportunities to let the world know just how good their sake can be.

There is just one concern that I have, and that is that there are only 13 active breweries up there. Of course, that is plenty if the goal is just to find great sake. Heck, one can be enough! But it is easier to develop a reputation as a sake-brewing region of diversity and quality when there are a large number of breweries with a large number of products from which to draw. With only 13 making sake up there, as good as each one of them might be, once having tasted the lineup, some folks might move on to other regions of note.

But in truth, while having a reputation that pervades the entire region can help in marketing the sake of that region, if most or even some of the breweries are doing well enough with their sake and its reputation, then the region should be considered successful.

Look for the sake of Hokkaido, especially but not limited to the ones mentioned above. It should continue to prove a very interesting region in the years to come.

The Young Guns of Sake Marketing

This article originally appeared in Sake Industry News Issue #21

Marketing from within has never been a forte of the sake industry. Yes, it should have been, and had the industry cooperated on that front years ago then sake would not be a measly six percent of all alcohol consumed in Japan. But the past is behind us, and it is interesting today to look at marketing efforts, and in particular cooperative marketing efforts, within the sake industry.

Marketing from within has never been a forte of the sake industry. Yes, it should have been, and had the industry cooperated on that front years ago then sake would not be a measly six percent of all alcohol consumed in Japan. But the past is behind us, and it is interesting today to look at marketing efforts, and in particular cooperative marketing efforts, within the sake industry.

Bear in mind that in the mid 70’s, sake was at its peak in terms of consumption, in fact the market was three times bigger than it is today. To put it more bluntly, sake has dropped to one-third of what it was at its peak in 1973.

But things are turning around – sort of, and in a number of ways. A shift to premium and more expensive products, as well as a changing of the guard in terms of company ownership are two of the more visible ways things are changing. Add to this the younger generation taking over seem to be a bit more willing to market than their predecessors.

Actually, that “younger” generation is not that much younger. 25 years ago when I began working in the sake industry, whenever I was with a bunch of brewers I was always the youngest in the group. Now I am almost without exception the oldest. Then again, I myself have aged a bit in the past 25 years. But I digress.

Back to sake marketing efforts, there are handful of examples of mostly young kuramoto that are from the same prefecture uniting to promote their sake as a team. Some of these have been around for a while and others are just getting started – or at least just kicking things into high gear. I have been interested in such efforts for a while but have not taken the time to list them all up and compare them. Yet, I am sure it is a moving target and hard to concretely assess. Nevertheless, Here is a rundown of a few that I think are worth noting.

Next Five

Next Five was formed in 2010, and is a group of five brewers in Akita Prefecture whose stated objective is to discover what sake of the next generation will be, and to be leaders going into that. They do a number of promotional activities, focusing mainly on three things: sake tasting events, other social and artistic events around which sake can be enjoyed, and all gathering each year at one of the five breweries and working together to make one sake together, with each one of them taking on one of the indispensable roles in sake brewing each time. I have also read that their plan was to have each member step down as they get older and replace them with like-minded younger brewers so as to keep the spirit of the next generation alive, although I am not sure if that has actually taken place. From my perspective they are the most visible, at least until recently.

Next Five was formed in 2010, and is a group of five brewers in Akita Prefecture whose stated objective is to discover what sake of the next generation will be, and to be leaders going into that. They do a number of promotional activities, focusing mainly on three things: sake tasting events, other social and artistic events around which sake can be enjoyed, and all gathering each year at one of the five breweries and working together to make one sake together, with each one of them taking on one of the indispensable roles in sake brewing each time. I have also read that their plan was to have each member step down as they get older and replace them with like-minded younger brewers so as to keep the spirit of the next generation alive, although I am not sure if that has actually taken place. From my perspective they are the most visible, at least until recently.

The five brands of sake involved are Shirataki, Aramasa, Yukino Bijin, Ippaku Suisei, and Harugasumi.

However, the idea was apparently inspired by a group of five brewers in Hiroshima that formed a group called the Konshikai, that gathered each year to critically assess each other’s sake in the spirit of improving all of their sake. Just last year I read of two of them exchanging kōji, in other words, two breweries (Kamo Kinshu and Ugonotsuki) did what they called a “kōji exchange,” which, as the term implies, exchanged koji for a co-branded couple of products. What an interesting idea!

There are others, and next time we lwill introduce Gokujo and Saku 13 from Nagano, as well as Date 7 from Miyagi, who produce shared brands and have been very active in the past couple of years.

In truth, though, none of these groups – as cool as they are – has much presence to speak of overseas. Sure, some of it gets exported, but very little at present. Nevertheless, their spirit of cooperation and the synergy it begets are a driving force in the sake industry, and promoting awareness of them both in Japan and outside Japan can only be beneficial.

A Closer Look at Omachi Rice

This article was originally published in Sake Industry News #5 Interested in more info like this? Subscribe, and enjoy your first two issues (and access to all back issues!) for free! https://sakeindustrynews.substack.com/

Studying rice varieties in excessive detail can be of dubious value. I say this because, as we all know, although the choice of rice strain is extremely important in brewing good sake, brewing methods, technology and the brewer’s skill are also of paramount importance. Which is more important? The answer to that is: all of them.

Studying rice varieties in excessive detail can be of dubious value. I say this because, as we all know, although the choice of rice strain is extremely important in brewing good sake, brewing methods, technology and the brewer’s skill are also of paramount importance. Which is more important? The answer to that is: all of them.

Setting that paradox aside, some rice strains – especially some of the “pure” strains – can be great fun and extremely interesting to study. So in that light, let us look in some detail at one of the most storied rice strains in use today: Omachi.

Currently, Omachi is the fourth most widely grown sake rice, behind the ubiquitous Yamada Nishiki, Gohyakumangoku, and Miyama Nishiki. It is also popular among sake fans, to the point it’s become almost cliché to say, “Omachi is my favorite rice.” (But I say it anyway…)

Omachi is a pure rice strain, in that it was not created through crossbreeding between two other strains, as almost all rice varieties in use today are. There are those that use the term “heirloom” to describe such strains, but I tend to shy away from that term since the definition of the word in reference to plant varieties is not clear, and not completely accurate in my assessment. But that is a conversation for another day.

The use of Omachi can lead to very distinctive sake. In short, if brewed to maximize the potential of its characteristics, sake made with Omachi rice will have higher acidity and sweetness, and a noticeable herbal astringency. In fact, “earthy and herbal” rather than “flowery and fruity” describes sake made with Omachi pretty well. A bit of time in the bottle can improve this as well. Also, to me, the overall flavor profile tends to be somewhat textured rather than silky smooth compared to Yamada Nishiki.

But beyond flavor, the history of Omachi is also quite fascinating, so let us take a look at some fun Omachi facts.

Omachi was discovered in 1859 in Okayama Prefecture. It was originally named Nihonsō in 1866, with the name changing to Omachi in 1922 when the government set up a system that included a reproduction process for keeping the lineage of rice strains pure. In fact, almost all Omachi grown today is still grown in Okayama Prefecture.

In 1895, the agricultural research center in Shiga Prefecture took some Omachi that was somehow different enough from the rest of the Omachi they had and renamed it Wataribune. Not surprisingly, different sources say different things, and at least one says that the Omachi grown in Shiga was actually brought up from Fukuoka, meaning it likely made its way via Okayama first. So, some say that Omachi and Wataribune are the same, others say that is not really true. I think it is more likely to be true, but you make the call.

Next, someone took this Wataribune rice and selected seeds from the shortest of the lot to grow again next year, in order to make it easier to harvest – kind of Darwinism in reverse. Why would they do that? Because if the rice stalks are too tall, they fall over before being ready for harvest, which can lead to germination resulting in the rice becoming unusable for brewing. This is one of the drawbacks of Omachi: it has tall stalks and is difficult to grow. This shorter variation of Wataribune became known as Tankan Watribune (short-stalk Wataribune).

Almost all sake rice grown today is a result of crossbreeding, and Omachi is in the roots of about 60 percent of all sake rice. There are a handful of variations of Omachi that are slightly different based on where they are grown such as Bizen Omachi, Akaiwa Omachi, Kairyō Omachi, and a couple more.

As mentioned above, it is the fourth most widely grown sake rice in terms of volume, but the top three are grown in much larger volume, with the gap in volume between Miyama Nishiki and Omachi being significant. Yamada Nishiki is grown in volumes somewhere around ten times that of Omachi.

One more anecdote: Long ago, several strains of Japonica rice were brought over to the USA by Japanese folks that emigrated there. Records show that one of these varieties was Wataribune (AKA Omachi), which back then was also used for eating. That Wataribune was crossbred again across several generations with a handful of other rice strains and today is known as Calrose. A large percentage of sake produced in the USA is made using Calrose rice, which is also used for eating in the US. However, it no longer resembles its venerated ancestor, making it a bit of a stretch to say Omachi lives on in the US.

So, in review: Nihonsō = Omachi = Wataribune = Tankan Wataribune = one of the parents of Yamada Nishiki. Or at least, that’s pretty close to the facts.

Obviously, not all sake rice has such a colorful ancestry, nor so many famous relatives. Most, in fact, have much fairly uninteresting developmental backgrounds, making it all the more important to convey the history of the more interesting examples such as Omachi from Okayama.

Interested in more info like this? Subscribe, and enjoy your first two issues (and access to all back issues!) for free! https://sakeindustrynews.substack.com/

Slightly Gassy Sake

Trend or sporadic anomaly? You make the call.

Trends can be difficult to identify, at least real ones. And people are always looking for them; folks are always asking about what is new in the sake world, and what trends are appearing. But amongst the plethora of new ideas and styles of sake that appear from time to time, how many are really a trend and how many are just an anomaly?

Trends can be difficult to identify, at least real ones. And people are always looking for them; folks are always asking about what is new in the sake world, and what trends are appearing. But amongst the plethora of new ideas and styles of sake that appear from time to time, how many are really a trend and how many are just an anomaly?

A useful observation to which I regularly refer to is this: there are about 1200 licensed sake breweries in Japan. A very rough estimate is that there is an average of about 20 products from each one. Some have three, others have 50, but the average is probably around 20 or so. Doing that math (1200 x 2) yields 24,000 products, so let’s round that up to 25,000 sake items on the Japanese sake market.

If 25 products of a particularly bent appear on the market over the span of a year or two, that is one tenth of one percent of all that are out there. Is that a trend? Hardly. But folks do like to latch on to things and read a lot into them. And, admittedly, there are actual trends that do appear from time to time, so the tendency to look for them is not at all misplaced.

One such development that has manifested in the sake world over the decade or so is “slightly gassy sake.” As cumbersome as that wording may be, it is accurately descriptive, and there is no real or official term for it. There are currently just a handful of these sake out there, but they are very visible products from extremely popular brewers, and as such attract a decent amount of attention. While probably not enough to constitute a trend, you’ll want to know about them and why and how they are as they are.

“Slightly gassy sake” is, just like it sounds, sake with a very small amount of carbon dioxide remaining in it.

Note, we are not talking about full-on sparkling sake, which is a completely different animal altogether and is much closer to being a full-fledged trend, replete with proper nomenclature and a sector of the industry that actively promotes it. Such sparkling sake is made by creating more gas in the bottle via secondary fermentation, although there are other methods as well. “Slightly gassy sake,” or SGS for the remainder of this article, contains a small amount of gas that remains from the original fermentation, but that’s all. (We will look at the category of sparkling sake in a future feature.)

Note, we are not talking about full-on sparkling sake, which is a completely different animal altogether and is much closer to being a full-fledged trend, replete with proper nomenclature and a sector of the industry that actively promotes it. Such sparkling sake is made by creating more gas in the bottle via secondary fermentation, although there are other methods as well. “Slightly gassy sake,” or SGS for the remainder of this article, contains a small amount of gas that remains from the original fermentation, but that’s all. (We will look at the category of sparkling sake in a future feature.)

Although not at all official, the term “gasu-khan” is often used to refer to what I am calling SGS here. And while full-on sparkling sake very often has a lower alcohol content, as low as six to eight percent, SGS is usually the full 16 percent or so.

SGS is made by pressing the sake, and getting it to the bottle as soon as possible, and with as little manhandling as possible. This lets just  a bit of the copious amounts of carbon dioxide that was there during fermentation to remain in the sake. The gas does not have a chance to escape or be blown off by sloshing it through pipes, pumps and processing on the way to the bottle. Note, once it is in the bottle, pasteurization will not make it go away, so SGS is not at all limited to namazake.

a bit of the copious amounts of carbon dioxide that was there during fermentation to remain in the sake. The gas does not have a chance to escape or be blown off by sloshing it through pipes, pumps and processing on the way to the bottle. Note, once it is in the bottle, pasteurization will not make it go away, so SGS is not at all limited to namazake.

While everyone does it at least a little bit differently, some brewers will bring the equipment used to press and bottle the sake right up to the tank to minimize the potential for lost gas. There are even a couple of proprietary methods out there as well.

In most of these products the effect is subtle, although in some it may be more overt than others. Flavor and aromas are not affected, and sometimes you may be left wondering if any gas was even there in the first place.

Note, there is nothing about this on the labels of these products, at least not that I have seen. They don’t really promote this aspect of it; it’s just kind of there. It certainly gets talked about, but more of as a highlight to an already good product.

The brewers that produce these products usually only create one or two products with this characteristic. There are exceptions, like Kaze no Mori (Nara) that makes a lineup of ‘em, but that is even less common.

Other well-known and popular producers that make one or more SGS products include Aramasa (Akita), Kamoshibito Kuheiji (Aichi), and Azumi Ichi (Saga). Recently I discovered another, Junsei which is made by Fukunishiki (Hyogo). There are others, of course, but just a handful.

What’s the point? The small amount of fine-grained gas can add a fresh touch, a new kind of appeal, and a nice accent. Most people like it, I guess, but I will admit that I find it to be a bit distracting. Not hugely, mind you, just a bit. Given the choice, most of the time I would prefer it to not be in my sake. For a few sips, or for one glass? Yeah. Fun. For a session? Jama. It stands in the way of full enjoyment.

So in truth, the expression “not a fan” might apply here. But that is just me! Many folks seem to enjoy it.

Will this kind of thing continue to grow? Will more and more products with this SGS character appear on the market? In my opinion, no. I think that the ones that are out there will continue to do well, but I do not see many more breweries jumping on that bandwagon. It can be fun and tasty for sure, but the small gassy touch does not unequivocally improve the product, and it does not add tangible value. It is also an added hassle for the producer.

Will this kind of thing continue to grow? Will more and more products with this SGS character appear on the market? In my opinion, no. I think that the ones that are out there will continue to do well, but I do not see many more breweries jumping on that bandwagon. It can be fun and tasty for sure, but the small gassy touch does not unequivocally improve the product, and it does not add tangible value. It is also an added hassle for the producer.

Yet it is an appealing and welcome alternative style that is enjoyed by many sake aficionados, so we may in fact see at least some continued growth, even if it never becomes a bona fide trend.

Note, this article originally appeared in the November 1, 2019 edition of Sake Industry News. If you are interested in a slightly deeper dive into the sake world than this newsletter usually provides, please consider subscribing.

Know more. Appreciate more.

Know more. Appreciate more.

Interested in learning more about sake, and the industry in Japan that makes it? Subscribe to Sake Industry News, a twice-monthly newsletter covering news from within the sake industry in Japan. Learn more and read a few sample issues here.

Masu, Salt, and Taruzake

Many people have had the experience of drinking sake from a small wooden box, often with a pinch of salt on one corner. We may hear that this is one traditional way to drink sake. What is behind this custom?

Many people have had the experience of drinking sake from a small wooden box, often with a pinch of salt on one corner. We may hear that this is one traditional way to drink sake. What is behind this custom?

Those small boxes are known as masu, and were long ago used very commonly to drink sake. The wood they are made of is sugi, sometimes called Japanese cedar, but more correctly cryptomeria.

Originally, they were actually a measure of rice (about one meal’s worth), and as they were readily available and cheap, they came into use as drinking vessels as well, especially at the sake pubs of olde. The volume these masu hold eventually came to be the standardized single serving volume: 180 milliliters (just about 5.5 ounces).

Since sake long ago was fermented in wooden tanks, and stored in wooden casks, the woody notes that might be imparted by serving in a masu might not be so noticeable. But having said that, even when wooden tanks were used (or are used, as there is a mini-renaissance of wooden tanks these days), there were aired out and used for water or rice first, to blow off the woody smells. So wooden tanks did not likely overdose the sake with woody essences. But then yet again, sake back 100 years ago was heavier, richer and often sweeter than the sake of today.

Since sake long ago was fermented in wooden tanks, and stored in wooden casks, the woody notes that might be imparted by serving in a masu might not be so noticeable. But having said that, even when wooden tanks were used (or are used, as there is a mini-renaissance of wooden tanks these days), there were aired out and used for water or rice first, to blow off the woody smells. So wooden tanks did not likely overdose the sake with woody essences. But then yet again, sake back 100 years ago was heavier, richer and often sweeter than the sake of today.

Which is why the refined and comparatively delicate sake of today is perhaps better off served in some other vessel, one that is decidedly neutral and that will not impart aromas of any kind to the sake. As modern sake is brewed in porcelain-lined steel tanks, the woody scents of long ago have now been replaced by fruit, flowers, and a whole host of other aromas. It would hardly be fair to the brewers to force these to compete with the woody influence of a masu!

There are, by the way, lacquered masu that allow one to enjoy the traditional feel of drinking from a masu, while enjoying the fruits (no  pun intended) of modern sake brewing skills. (Actually, most of them are plastic, i.e. “genuine artificial lacquerware,” but I digress.)

pun intended) of modern sake brewing skills. (Actually, most of them are plastic, i.e. “genuine artificial lacquerware,” but I digress.)

The pinch of salt on the corner is interesting as well. According to one source (there are sure to be many opinions), the salt should not be placed just on the corner, but a bit to the side of it, so that when one drinks, the salt touches the corner of the lips, not dead center. This allows the sake to be the main flavor, with the salt on the side. Note, the salt should not be allowed to fall into the sake.

Why salt? According to the same source (a historian at one of the large breweries in Japan), the salt was more for the proprietor than the consumer. Salt is often used in purification rituals in Japan, as well as for good luck in drawing customers to places of food and drink. Apparently this superstition was one big reason for putting the pinch of salt on the edge of the masu. But again, there are sure to be other interpretations.

Why salt? According to the same source (a historian at one of the large breweries in Japan), the salt was more for the proprietor than the consumer. Salt is often used in purification rituals in Japan, as well as for good luck in drawing customers to places of food and drink. Apparently this superstition was one big reason for putting the pinch of salt on the edge of the masu. But again, there are sure to be other interpretations.

Also, as mentioned above, a century ago and earlier sake was bolder and often sweeter, and simple things like salt and miso were often used as snacks while drinking. A bit of salt was also thought to stimulate the appetite and make the sake itself more enjoyable, a sentiment with which I will readily agree.

Also, not all sake today is light and ephemeral. If anything, traditional heavier types, like kimoto, yamahai, and just plain big-ass sake, are making much more visible these days, which is great. It increases the veritable variety of proper sake that available to us all. And on the food side, there are certainly much more enjoyable food and snacks for sake today than just a pinch of salt, although such simplicity certainly has its place.

There is, however, one time and one type of sake for which masu and salt are still commonly used today. Just after New Year’s Day, when people gather for traditional year-opening ceremonies in communities, families and companies, taru-zake is often the sake of choice. Taru-zake is sake that has been stored in the traditional cedar cask, not bottles, deliberately to induce that woody taste and aroma. While it may not be as hoity toity as a fine ginjo, taru-zake has its charm and appeal, and is perfectly enjoyable.

There is, however, one time and one type of sake for which masu and salt are still commonly used today. Just after New Year’s Day, when people gather for traditional year-opening ceremonies in communities, families and companies, taru-zake is often the sake of choice. Taru-zake is sake that has been stored in the traditional cedar cask, not bottles, deliberately to induce that woody taste and aroma. While it may not be as hoity toity as a fine ginjo, taru-zake has its charm and appeal, and is perfectly enjoyable.

This is precisely when wooden masu are used, with woody sake, and this is when even today we can enjoy a good, strong-flavored sake with a pinch of salt on the corner of the masu.

Should it be available near you, bring in 2021 with a tad of sake tradition, and a prayer for peace and joy on the planet. Prepare for that now by procuring a few masu and some taruzake. The salt? You likely have that on hand already!

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Know more. Appreciate more.

Know more. Appreciate more.

Interested in learning more about sake, and the industry in Japan that makes it? Subscribe to Sake Industry News, a twice-monthly newsletter covering news from within the sake industry in Japan. Learn more and read a few sample issues here.

The Leverage of Post-Brewing Processing Steps

The sake brewing process is a fairly intricate, convoluted affair that sounds complicated at first listen, and only gets more so as one gets deeper into it. And that is precisely the appeal of sake: you’ll never know it all. If one were to streamline the explanation so as to convey it in just a few sentences, it might sound like the below. While it is a super simplification, it is enough to lay the foundation for the topic here.

The sake brewing process is a fairly intricate, convoluted affair that sounds complicated at first listen, and only gets more so as one gets deeper into it. And that is precisely the appeal of sake: you’ll never know it all. If one were to streamline the explanation so as to convey it in just a few sentences, it might sound like the below. While it is a super simplification, it is enough to lay the foundation for the topic here.

“To make sake, a yeast starter that has a very high concentration of yeast must first be created so as to allow the subsequent fermentation to continue unfazed by all the stray micro-organisms dropping in for a visit. But to get sugar to feed that yeast, some of the rice must be inoculated with a mold, koji mold, that provides enzymes and breaks down starch molecules to glucose.

“After the yeast starter is adequately prepared, the size of the batch is essentially double three times over four days by adding more rice, moldy rice, and water, with the purpose of dividing it up into three separate additions being to keep the yeast population high and strong. After the 20- to 30-day fermentation period, the remaining rice solids are filtered out through a press to yield clear sake.”

There you have it, in all of its tradition-insulting oversimplifying glory. What we have at this point is undeniably sake. But if the explanation of the process were drawn out over several pages, it would likely be then suffixed by something akin to, “oh, then, you might charcoal filter it, you might pasteurize it, store it, cut it with water, maybe pasteurize it again, bottle it, and ship it.” This makes it sound as if once fermentation is completed and you have “sake”, the rest is a simple matter of course, and not much to be concerned about. But, as you may have surmised, it is not that simple. Sake never is.

Without a doubt, the “after it’s sake” processing has just as much to do with the nature of the final product as does the complicated  brewing process before it. One brewer told me that he considers the last few steps, or “after-care” as he called it, to be about 51 percent of the quality of a sake, and the complicated pre-pressing steps only 49 percent. A completed sake can take any one of a million paths, depending on the methodology, forcefulness, order and especially the timing of these “post-brewing” processes.

brewing process before it. One brewer told me that he considers the last few steps, or “after-care” as he called it, to be about 51 percent of the quality of a sake, and the complicated pre-pressing steps only 49 percent. A completed sake can take any one of a million paths, depending on the methodology, forcefulness, order and especially the timing of these “post-brewing” processes.

Perhaps the easiest thing to look at as an example would be pasteurization. When a sake is pasteurized by essentially warming it up for a short spell, various things happen, most notably bacteria are killed, and enzymes are deactivated. This provides great stability to the product. But the timing of this step ( usually done twice, by the way) is a huge factor in how a sake matures.

Consider a freshly pressed tank of sake. It has residual enzymes, a bit of sugar and starch and a few stray yeast cells still hanging around and looking for some action. Like all late-night partiers, these folks will interact a bit and their presence will be felt. But once the police-sweep of pasteurization clears out the ‘hood, these colorful characters are gone, as is the potential effect of them having been there.

Waxing technical again, sake matures much more quickly when it is stored unpasteurized, and much more slowly after it has been pasteurized. So the longer a brewer waits to put the heat on, the fuller, richer, meatier, more pronounced-in-flavor the sake has a tendency to be.

Of course, nothing is quite that simple. It will mature after pasteurization, just not as vividly.

The point being, there are no hard and fast rules for the brewers to follow. What kind of sake is the brewer aiming for? How close or far from that is this particular batch? How slowly or quickly will that puppy in particular mature? When can it be expected to be shipped? How much time is there to play with, both before and after pasteurization? Can it be stored cold or must it be at room temperature, and what are the effects of that environment on what it is and what it will be? It is as frustratingly difficult as any other step in the brewing process, and exerts as much leverage as well.

The point being, there are no hard and fast rules for the brewers to follow. What kind of sake is the brewer aiming for? How close or far from that is this particular batch? How slowly or quickly will that puppy in particular mature? When can it be expected to be shipped? How much time is there to play with, both before and after pasteurization? Can it be stored cold or must it be at room temperature, and what are the effects of that environment on what it is and what it will be? It is as frustratingly difficult as any other step in the brewing process, and exerts as much leverage as well.

Traditionally, sake was pasteurized once very soon after brewing, then stored in a storage tank, and pasteurized again on its way to the bottle to ward off the effects of any bacteria it may have encountered on the way from said tank to said bottle. Today, however, there are countless variations of this once-standard way of processing.

Another not-so-simple issue is bottling. From long ago, sake was matured for six months or so in large tanks, then bottled later. But lately there has been a significant movement amongst craft brewers toward storing in bottles, not tanks, which calls for a much larger amount of warehouse storage space.

Huge. Still, many brewers find this yields a more fine-grained sake. Sake handled this way if often pasteurized just once, and more mildly as well.

The duration of maturation and dilution with water are similar in the myriad of affects that will result from different choices. Put them all together, and you can begin to see that the permutations are endless. Also, keep in mind there is no right way to do anything. It is all a function, obviously, of what style of sake the brewer intends to make.

Fine-grained, or big-boned? Light and dancing or settled and earthy? A one-glass sake or a session sake? All have their place and fans, and all call for different after-care.

At a tasting a while back of Shizuoka Prefecture sake, I made my way to the Kikuyoi booth. Shizuoka sits about an hour south of Tokyo,  and is the home of half of Mt. Fuji, as well as Japan’s best green tea and best wasabi. It has been a haven of good sake since the late 80s, rather than for centuries, but it is making up for lost time with a mighty vengeance.

and is the home of half of Mt. Fuji, as well as Japan’s best green tea and best wasabi. It has been a haven of good sake since the late 80s, rather than for centuries, but it is making up for lost time with a mighty vengeance.

Kikuyoi is brewed by owner-to-be and toji Takashi Aoshima. For now, let us just say there are great stories behind this brilliant guy, having looked askance at his sake-fate initially, then later returning to it with an unrivaled passion. His sake is settled and simple, delicately rich, and decidedly not ostentatious. I make a point of tasting it a lot – yea, verily, drinking it a lot – and as I worked across his table I noticed that the degree of maturity this time was exquisitely precise – more so than I recalled. The flavors stood out from their mellow background just perfectly.

Catching Aoshima-san for a brief moment after my run-through, I told him as much. “Your sake seems to be matured almost perfectly,” I offered.

“So! That’s right!” he blurted enthusiastically. “I agree wholeheartedly. I finally got the knack of it; it’s all in the timing of the pasteurization,” he explained.

“So now,” he continued, “I have, like, zero time. I am basically brewing in the winter, growing rice in the summer, and fiddlin’ with pasteurizing my sake and stuff like that in the gaps between.” The fact that he was beaming happily about his fate made it hard to feel sorry for him. He is famous for the dedication and energy he puts into brewing his sake, and it was evident in our conversation.

When next you come across an explanation on a label for from brewer on something as innocuous-sounding as pasteurization, bottle storage, or charcoal filtration remember that, as simple as those steps sound in comparison to koji and yeast starters and multiple additions, they carry quite the clout when it comes to the nature of the final sake.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Know more. Appreciate more.

Know more. Appreciate more.

Interested in learning more about sake, and the industry in Japan that makes it? Subscribe to Sake Industry News, a twice-monthly newsletter covering news from within the sake industry in Japan. Learn more and read a few sample issues here.

Assessing Sake in the Old Days

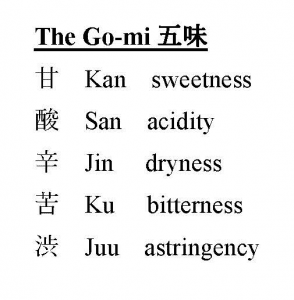

Limited to only the five “Go-mi” terms

Describing the flavors and aromas of sake can be a challenge. It doesn’t have to be, but often we make it so. In the end, if we like it then we like it. No descriptors are necessary if it is just for ourselves.

Describing the flavors and aromas of sake can be a challenge. It doesn’t have to be, but often we make it so. In the end, if we like it then we like it. No descriptors are necessary if it is just for ourselves.

However, if we want to convey the appeal of a sake, how it tastes and smells, and what makes it special and different from other sake, then we need words and descriptors that people can more or less agree upon.

And these days there are lots of resources available for this kind of thing. Some organizations have lists of terms to which students should try to limit themselves to ensure that people are using the same words, which is surely one effective strategy. Flavor and aroma wheels are available too from a range of people and sources.

All are useful! And terms like this are more important to some than to others, for sure. On top of that, there are plenty of folks that rely upon their own lexicon developed through years of experience, and furthermore, there are people that are not really interested in concrete descriptors. But in the end, it is better to have them than to be caught short on words – or to be inconsistent – when the occasion calls for it. Such terminology gives those with experience something to say, and those without it a foothold from which to ascend.

But not so long ago, sake professionals in Japan did not have such – or need – such an arsenal of expression. Remember that long ago, people drank what was local. And “I like it” was often synonymous with “it’s all I can get ‘cuz it’s all they sell near me!” Furthermore, back then there was far less varieties of sake from which to choose. The local brewery to which one might be limited could have three or four products – only!

The sheer variety of sake available these days from any one brewery is mind boggling compared to what it might have been as recently as 50 years ago. So for a plethora of reasons, flavor wheels and official lexicons simply were not necessary. But today, they are. And we have them! And fortunately, we also have legions of sake fans and professionals that are willing to at least try to express sake flavors and aromas in concrete words.

50 years ago. So for a plethora of reasons, flavor wheels and official lexicons simply were not necessary. But today, they are. And we have them! And fortunately, we also have legions of sake fans and professionals that are willing to at least try to express sake flavors and aromas in concrete words.

So, what terminology did they use long ago? How did sake pros talk to each other before we had so many varieties of sake and before modern infrastructure made the de facto market for any brewer much broader than the local yokels?

Five terms. That’s what they had; that’s it. Limiting things in that way is either extremely streamlined or needlessly restrictive. But worked for centuries for the sake industry, so there must be some merit to it!

So what are those five terms? Avoiding a long linguistic discussion on characters and their possible multiple readings, the five flavors are as below.

That’s it! Sweet, dry, acid, bitter, astringent. The are collectively referred to as the go-mi, or “the five flavors.” Long ago when judges would assess a sake, they would look for these five facets amidst the flavors and aromas, and importantly, the balance between them. All must be present; none can stand out from the others too much. It is certainly a very interesting concept, and brutally simple as well.

That’s it! Sweet, dry, acid, bitter, astringent. The are collectively referred to as the go-mi, or “the five flavors.” Long ago when judges would assess a sake, they would look for these five facets amidst the flavors and aromas, and importantly, the balance between them. All must be present; none can stand out from the others too much. It is certainly a very interesting concept, and brutally simple as well.

It also has its shortcomings. For example, to many people, sweetness and dryness are two sides of the same coin, are they not? And astringency is not an everyday concept in the West, although it is used much more in Japan. Furthermore, it overlaps with acidity somewhat.

Imperfections notwithstanding, limiting things in this way does provide some focus. But it surely makes it harder to convey to others what a sake actually tastes and smells like.

Of course, this discussion is admittedly laced with a healthy dose of hyperbole. In other words, even in the old days, surely people used more than five words to describe their sake, and to convey it. The use of these was probably limited to technical assessments and professional judges. Also, while these days no one “on the street” assesses sake this way, even these days there are still some older kuramoto and toji that settle down into this focused approach when seriously tasting sake.

As a side note, when normal people talk to each other about sake, rather than the five single syllable readings written above, we say amai (sweet), sanmi (acidity), karai (dry), nigai (bitter), and shibumi (astringency). You are much more likely to hear these words in a conversation.

In truth, these five terms are close to being relegated to a historical anecdote. But at the same time it is important to remember how things were done for so long, especially something that worked so well and for so many. And at the same time, to convey the wonders and appeal of sake to the world at large, modern terminology and expression is key. Like everything related to sake, including the go-mi, balance is key.

The 2nd Sake Professional Course Live Online, October 2020

On October 3, 4, 10, 11, 17 and 18 I will be running the second Sake Professional Course Live Online, to be held via Zoom on those five consecutive weekend days. The seminar will be run from Japan at a strategically selected time so that viewers in other parts of the world can watch it as well.

On October 3, 4, 10, 11, 17 and 18 I will be running the second Sake Professional Course Live Online, to be held via Zoom on those five consecutive weekend days. The seminar will be run from Japan at a strategically selected time so that viewers in other parts of the world can watch it as well.

The content of the course will be identical to the live, in-person Sake Professional Course, and the exam for Certified Sake Professional will take place online as well on October 24. We will run optional sake tastings at the end of each session, for those that want to purchase the sake. In truth, a handful of details are not yet set, and in fact Sake World newsletter readers are the first to know about this!

Learn more and download more information here. If interested, please send me an email, and I will get back to you as soon as the details are settled.

“No Sake Stone Remains Left Unturned!”