2017 National New Sake Compeition Report

In May, the 105th Zenkoku Shinshu Kanpyoukai was held in Japan. The official English name for this contest is the Japan Sake Awards, but the literal translation is much more descriptive if slightly unwieldy: the National New Sake Tasting Competition. It is the longest running competition of its kind anywhere in the world. Those interested can find more information in the archives of this newsletter (which go back to 1999!), in particular in the June or July editions for each year.

In May, the 105th Zenkoku Shinshu Kanpyoukai was held in Japan. The official English name for this contest is the Japan Sake Awards, but the literal translation is much more descriptive if slightly unwieldy: the National New Sake Tasting Competition. It is the longest running competition of its kind anywhere in the world. Those interested can find more information in the archives of this newsletter (which go back to 1999!), in particular in the June or July editions for each year.

But to save you the hassle, here is a summary of the main points of this prestigious competition.

The sake submitted is not stuff you can normally buy, but rather daiginjo or junmai daiginjo made specifically for this contest. It is brewed to have a minimum of faults, but still seem unique and special. I often refer to it as “daiginjo on steroids.”

This year, 860 of Japan’s 1200 sakagura submitted an entry to the contest. Each company is allowed to submit one sake per brewing license, i.e. one per brewing facility owned. Some big companies own more than one facility so they would be permitted one for each.

Almost all of it is not junmai because using the added-alcohol step brings out more aromas and flavors. But this year, 156 of the 860 submissions were junmai, up from 139 a year ago. Clearly more brewers are interested in trying to win with junmai sake.

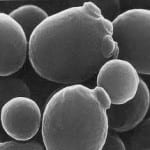

Koji being cultivated in small trays

Sake is tasted blind in round one, and about half (this year, 437 to be exact) make it to round two. They are then tasted blind again, and about half (this year, 242 to be exact) of these will be designated as gold, the rest that made it into the second round are designated as prize-winners (the term “silver” is not used, although the gist is the same).

This year, 242 won gold, and 215 won silver. While prestigious within the sake industry, it is not that commonly used in marketing as the average consumer has no idea this contest even exists.

For the seventh time in eleven years, and fifth in a row, Fukushima Prefecture won more golds than any other prefecture, and as has been the case for the past decade, the entire Tohoku region did very, very well. In fact, much more interesting than Fukushima – with all due respect to their accomplishments – was Miyagi, where 20 sake out of the 23 total submitted got gold! Two more got silver as well. This was an unprecedented result.

This year, brewers were whining that the Yamada Nishiki rice that is most commonly used for contest sake like this was not dissolving easily in the fermenting mash. This means tight flavor profiles with little flavor expressed. But this proved to not be too much of a problem, although flavor profiles seemed to vary quite a bit from region to region.

Much winning sake was on the sweet side, with extra glucose to balance out bitterness contributed by yeasts that give fruity aromas. This seemed especially true in Fukushima, and only slightly less so in Miyagi.

While the sake submitted is not usually sake desitned for the market, the flavors, aromas, styles and leading prefectures are a harbinger of where sake is currently headed. Therein lies the contest’s appeal.

There is so much to be said about this competition: the changes over the years, the remarkably-few-yet-still-there-to-some-degree politics, the history, the records, the reasons it came to be. Much of that can be dug up in the archives of this newsletter, (see the end of the newsletter for more on that) but more importantly it seems as though amidst today’s sake popularity, more brewers and consumers as well are showing an interest in this historically and culturally significant competition.

You can see the results in Japanese here and in English here .

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Sake Professional Course in Denver, Colorado

August 28-30, 2017

From Monday August 28 to Wednesday August 30, 2017, I will hold the 27th North American running of the Sake Professional Course at the University of Denver, (Fritz Knoebel School of Hospitality, Daniels College of Business) in Denver, Colorado. The content of this intensive sake course will be identical to that of the Sake Professional Course held each January in Japan, with the exception of visiting sake breweries.

From Monday August 28 to Wednesday August 30, 2017, I will hold the 27th North American running of the Sake Professional Course at the University of Denver, (Fritz Knoebel School of Hospitality, Daniels College of Business) in Denver, Colorado. The content of this intensive sake course will be identical to that of the Sake Professional Course held each January in Japan, with the exception of visiting sake breweries.

The course is recognized by the Sake Education Council, and those that complete it will be qualified to take the exam for Certified Sake Specialist, which will be offered on the evening of the last day of the course.

You can learn more about the course here, see the daily syllabus here,and download a pdf here. If you are interested in being in the mailing list for direct course announcements, please send me an email to that purport.

Testimonials from past graduates can be perused here as well.