Why make it harder than it needs to be?

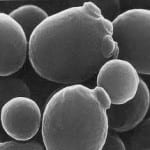

There are countless varieties of yeast used in sake brewing today. Yeast converts sugar (that has been created when enzymes in the koji break down starch in the rice) into alcohol. So, no yeast, no sake. But it does much, much more. But the most evident expression of yeast in sake is aroma. Basically, yeast yields aromas.

There are countless varieties of yeast used in sake brewing today. Yeast converts sugar (that has been created when enzymes in the koji break down starch in the rice) into alcohol. So, no yeast, no sake. But it does much, much more. But the most evident expression of yeast in sake is aroma. Basically, yeast yields aromas.

If you smell banana and melon in your sake, that comes from the yeast. If you smell apple and anise, that comes from the yeast. If you smell bacon and smoke, that comes from bad yeast.

Almost all brewers select and manually add the yeast of their choice for each sake. And, in a very few cases, yeast can drop in from the air and naturally occur. These can be categorized in a handful of ways, most usefully perhaps in terms of “classic” yeasts and “modern” yeasts, with the former giving more overall balance and the latter being more aromatic.

But another way to categorize yeast is “foaming” and “non-foaming.” The difference is just as the terms imply: foaming yeast froths up on the top of the fermenting mash, whereas non-foaming yeast does not. Other than that, they are pretty much the same.

Foaming yeast are much, much more common and were in fact the standard for centuries. Why are the foamless ones foamless? What happens, it seems, is that most yeast cells will cling to bubbles of carbon dioxide that are created and then rise to the surface. Foamless yeast cells, on the other hand, for whatever reason do not cling to these bubbles and so are not carried up, up, and away. Since the bubbles are unencumbered, they pop, and there is no foam rising high above the mash.

Foaming yeast are much, much more common and were in fact the standard for centuries. Why are the foamless ones foamless? What happens, it seems, is that most yeast cells will cling to bubbles of carbon dioxide that are created and then rise to the surface. Foamless yeast cells, on the other hand, for whatever reason do not cling to these bubbles and so are not carried up, up, and away. Since the bubbles are unencumbered, they pop, and there is no foam rising high above the mash.

Many yeasts have both foaming and non-foaming manifestations. An organization called the Nihon Jozo Kyokai (Brewing society of Japan) distributes the lion’s share of sake yeast to the industry. The yeast varieties they distribute are numbered, as in number 6, 7, 9, 10, 14, and 18. These are the most commonly seen, although there are others. When a -01 is added, that indicates a foamless version. So 601 is a foamless 6, 701 is a foamless 7, and 901 is a foamless 9.

During production, the two types of yeast behave very differently.

For instance, since the foam rises in great swaths during fermentation, brewers cannot fill a fermentation tank to the top with ingredients when using a foaming yeast. If they did, the foam would overflow, taking yeast with it, and fermentation would peter out. Using a foamless yeast eliminates this problem, since there is no foam to overflow. So the brewers can fill the tank to the top from the beginning, and this means brewers can get about 25 percent more sake from each tank. That is significant.

Also, when foam does rise and fall, the remains that cling to the side of the tank are a veritable hotbed of bacterial activity, an orgy of undesirable microorganisms just hankerin’ to drop back in and do damage to the unsuspecting ambrosia-in-waiting below. So this must be assiduously cleaned off by the brewers. Not only is this hard and time consuming work, it can be dangerous. So by eliminating the foamy remains, time, labor, and risk are spared. Yet one more advantage of foamless yeast is that the yeast cells move and work a bit more freely, so that fermentation proceeds a smidgeon faster and can finish a day or two earlier.

Also, when foam does rise and fall, the remains that cling to the side of the tank are a veritable hotbed of bacterial activity, an orgy of undesirable microorganisms just hankerin’ to drop back in and do damage to the unsuspecting ambrosia-in-waiting below. So this must be assiduously cleaned off by the brewers. Not only is this hard and time consuming work, it can be dangerous. So by eliminating the foamy remains, time, labor, and risk are spared. Yet one more advantage of foamless yeast is that the yeast cells move and work a bit more freely, so that fermentation proceeds a smidgeon faster and can finish a day or two earlier.

So foamless yeast is faster, easier, and increases per-tank yields significantly. This naturally begs the question: why in the world would a brewer not use a foamless yeast?

In a word (or two): sensory input. Visual data. Insights that chemical measurements cannot provide.

I recently visited the brewer of Matsuo, Ryuta Tanaka, deep in the backwoods of mountainous Nagano prefecture. As we meandered through his kura, we eventually made it to the moto room, where all the yeast starters are created. Most sake here is made using a yeast known as Number 14, the non-foaming counterpart of which is 14-01.

“All of our sake is made using foaming yeast; 14-01 is fine, but I gotta have the foam,” he began. “Sure, I give up yields. Sure, it is more of a hassle. But this sake stuff has a life of its own; it doesn’t always proceed as expected. So the more info I can get, the better I can roll with it and guide it to end up as tasty.”

During the 20 to 35 day fermentation period, the surface of the mash will change daily. After a few days, the foam will appear, peaking at about the tenth to the twelfth day, and then slowly collapse and contract into a skin-like surface. Experience and intuition let a master brewer look at the foam on any day and know how healthy the yeast is, and what the sake will end up tasting like when done. Foamless yeasts, for all their benefits, do not offer nearly as much visual feedback as to how the fermentation is proceeding.

During the 20 to 35 day fermentation period, the surface of the mash will change daily. After a few days, the foam will appear, peaking at about the tenth to the twelfth day, and then slowly collapse and contract into a skin-like surface. Experience and intuition let a master brewer look at the foam on any day and know how healthy the yeast is, and what the sake will end up tasting like when done. Foamless yeasts, for all their benefits, do not offer nearly as much visual feedback as to how the fermentation is proceeding.

Tanaka-san continued. “With experience, it is amazing what I can tell from the appearance of the foam. F’rinstance, I can look at the foam on any given day and tell you what the nihonshu-do will be on the next day!” The nihonshu-do is the specific gravity, and it will tell the brewer how fast sugar is being produced and how fast it is being fermented. So it is a seminally important measurement to sake brewing.

“Usually, we have to measure that daily with a hydrometer; but I can eyeball it based on the foam,” he stated, obviously pleased with this. “That’s the way sake has always been made; brewers used their five senses to get the job done. They didn’t need no stinkin’ hydrometers!” While I admittedly took a bit of liberty with that translation, the gist was certainly the same.

Last month in this space we talked about sadistic sake fans. While their counterparts may exist in masochistic brewers, often the older, hassle-laden ways are, indeed, better. While there are certainly many opinions, increased sensory data is one reason for that.