SPC Learning Online Testimonials

(Certified Sake Professional Course)

I just completed the Level 1, Sake Professional Course Online with John Gauntner. This is the second time I have taken the SPC Level 1. I completed my first one in-person in Tokyo, and when I saw that John was offering the Level 1 online as a refresher course for alumni, I jumped at the chance!

Not only is John one of the most knowledgeable people in the sake world, his industry insight, and stories from the sake world, make the course one of the most enjoyable things I have done. You will not be disappointed and John’s motto, “no sake stone left unturned” is an understatement!! You will learn more than you ever thought you could about sake. Plus, John’s guided tasting will help you gain a new appreciation for Japan’s traditional, alcoholic beverage. Highly recommended.

Chris – Okinawa, Japan, October 2021

John Gauntner’s Sake Professional course was the third Sake educational program I had taken and by far was the most enjoyable and comprehensive. As a advisory teacher for the UK government for many years I have an extensive background in education and am probably not the easiest of students as I really want the content to be comprehensive, engaging and relevant. John delivered all of that and more!

His easy warm style of coaching enabled us all to freely discuss anything we were unsure of, he answered queries expertly and with grace, his obvious passion and knowledge enthused my learning and the lengthy lectures whizzed by so enjoyably that I was always surprised when they ended. The course book is comprehensive and the online exam covered the materials in detail.

John is a community builder, his compassionate style of delivery and respect for all the artisan makers and lovers of Sake means he has the deepest admiration from all who come into contact with him, anyone who wants to really delve into the world of Sake needs to do this course (whilst having a glass of Sake on hand of course!)

Marion Titmuss (October 2021)

John Gauntner’s Certified Sake Professional course is an incredible immersion into an awesome topic. Sake. Between an engaging dialogue and open communication of ideas and themes that flow around sake, I never felt any pretense and had a lot of fun while learning an immense amount of information. The class is concise and organized, but not stuffy and flows in an obvious manner that is explained thoroughly. Mr. Gautner truly is the sake evangelist and his passion can be seen in the many jaunts down geeky/informational rabbit holes that add nuance and specialness to the course as a whole. Thank you for being you John!

Zachary Geerson

John Gauntner’s Sake Professional Course Level 1 is an amazing resource for anyone looking to improve their sake knowledge. I highly recommend it to anyone working with Sake, whether selling, recommending, or promoting, the knowledge gained and connections made are incredibly valuable. The world of sake is often opaque and indirect, but with the guidance of John Gautner you are able to appreciate, understand, and further your knowledge in a way that is simply not possible even with years of self study. Highly recommended!

Austin

Essential not only for detail-oriented professionals but also very importantly for enthusiasts of Japanese culture—vividly rendered anecdotes and authoritative technical info, blended with affable style by John Gauntner—this is a broad and deep tour through regions, craft, and flavors.

—Balazs Bognar, architect and Partner at Kengo Kuma & Associates

I’m really so glad that I’ve taken John Gauntner’s Online Sake Professional Course. The course was very well-structured and balanced, covering pretty much everything one needs to know about Sake, including the current situation of the industry.

Elisabeth Llopis

I have been going to Japan annually since 2013. Sake was offered by many Japanese friends. Even though I own cocktail bars , I know very little about it. Covid-19 has halted all travels, but I was able to find John’s class online. After I obtained my CSP (Certified Sake Professional), I can say the course has exceeded my expectations. In one month, it is true that “No sake stone remains left unturned”. John laid out the fundamentals and roadmaps of sake for this introductory course. It does not mean it is easy. Some topics are quite challenging if you are not prepared.

I wish to continue my learning of sake. John would be my first choice for future studies.

Ethan, Victoria Canada (April 2021)

As a complete novice of not just Sake but the beverages industry in general, I was unsure if I could follow this course’s content. However, John did such a good job in explaining the material in a simple and concise manner that my worries turned into a fascination with the world of Sake by the end of the first lesson. The course is structured logically and John manages to give in-depth information about Sake through lessons that are engaging even through Zoom. Even though I joined with little prior knowledge, I could confidently say that I know enough about Sake to amaze my Japanese friends by the end of the course!

Cem Ertul

I thoroughly enjoyed the online Sake Professional Course. John’s knowledge of the topic and passion for it was evident. The lectures were very engaging. I haven’t heard someone talk about a subject with such ease and depth of knowledge in a long time. The technical aspects were explained extremely well, and the stories one only gains from years in the industry were very interesting, too. He was also exceedingly generous with his time in answering everyone’s questions. I would highly recommend this course and I look forward to taking the Advanced Sake Professional course in the future.

N. Peppler

May 2021

I am a Japanese native certified sake sommelier and have been educating sake for the past 5 years in the US. I took this class because I wanted to learn how I can explain “everything sake” better in English. If I were investing my time and money, I wanted to learn from the best and I am so glad I made the right decision. John has more than 30 years of experience in the sake industry, from introducing sake overseas, publishing the most comprehensive sake book in English, to being the first and only non-Japanese judge for Zenkoku Shinshu Kamoyoukai aka Japan Sake Awards. In this course, John has truly demonstrated his deep understanding of Japanese culture and sake tradition in western perspectives.

If you are really serious about learning sake to the next level, I would highly recommend John’s Sake Professional Course. It is not only extremely informative but also very fun and fascinating. John answered all of the detailed questions that I was never able to find an answer for. Now I am able to explain complex sake concepts in a much simpler way to my customers. His materials are well-organized and easy to follow. A virtual session worked well for me because if you missed any points, a recorded session was available for review. I can’t wait to take the in person tasting and brewery tour with John once available!

Ayaka Ito

Participating in the sake professional course was enjoyable and incredibly educational. The instructor, John Gauntner, was engaging as he drew upon his decades of personal experience to cover each aspect of the sake brewing process, varieties of sake, sake culture, and the current state of the industry. The pacing allowed students of varying backgrounds and interests to understand the material clearly, and the certification test was comprehensive without being overly stressful. I know I will continue to find the information useful, and I look forward to expanding my sake-related knowledge through the resources available via the Sake Education Council.

-Douglas Wagner

Asian Art Department, Denver Art Museum

If you are already aware of John Gauntner, there is no introduction needed and everything you expected and more will be learned throughout the first segment of the Sake Professional Course. For those still learning what junmai means, no worries, the course is also designed with you in mind. John provides a structured course exploring the history, processes, and nuances of sake. By the end, you will have a solid understanding of what sake is literally, historically, and culturally. If you are in the US, John has made it easy to at least procure sake for tasting. If not, he still provides a detailed list to procure the types of sake needed. The course has broken down the fundamental of tasting sake and provides a fantastic guide on the main characteristics. As someone who was familiar drinking sake, I came out having a higher level of clarity on what sake can taste like and a curiosity for what is out there.

Throughout the whole course and even before it started, John is readily available and will help you with any questions or concerns. Alongside all the information, you have an individual who has been part of the industry. Someone who can provide the insight of the what sake is and what it used to be. Again, the course is for anyone. From someone who wants to confirm their knowledge and experience to a newbie to the scene, John is there along the way to answer questions and share his experience. The only thing I regret is not taking course and drinking more sake.

Michael Kim

Highly recommend it to anyone who wants to start a career in the sake industry. Took the course in the most unfavorable time (Sat Sun 3am to 6 am) but I was never tired. John is an amazing teacher. His explanations stick to your mind. He is clever and accessible, some of the most important things for someone who decides to teach. His approach on sake and the sake industry is based on real experiences. Due to this, he could tell us so many stories. In the end, I felt like I as part of all of them. His selection of sakes is a plus. It is kind of a reference list you will have to follow your studies on sake. At the end, I was feeling ready to start working and, at same time, dive deeper in the sake world. I am glad to have taken this course and l will take the advanced level as soon as my economic condition permits.

Roberto Maxwell

I was motivated to take the Sake Professional Certification Course after hearing John Gauntner speak as part of the Japan Information & Cultural Center Virtual Lectures in their 2020 Guormet Series hosted by the Embassy of Japan. John is passionate about sake and eager to share his experience and knowledge on the subject. The course was fast paced and filled with a lot of useful information about the industry and its impressive history. It was a great experience that I would highly recommend, even for someone outside of the industry, like myself. The course was well planned, well delivered, and affordable. Kanpai!

Gordon Morris – Washington

SPC LO-4 was an extremely friendly and cordial webinar. I did know his in-depth knowledge about the Sake world through the past email letters and the books, however, the SPC Live Online was a truly different amazing world!!! John Gauntner’s passion for Sake and the eagerness of other participants inspired me to further efforts to deepen and expand my knowledge of Sake in English. I’m happy to complete this online course, especially as a qualified tour guide.

I’d like to recommend this course to all the Japanese who are engaged in the Sake Brewery Tourism. This would be the only opportunity to learn about Sake in detail, in English. I believe his enthusiastic, thoughtful lecture was an impressive testament to his love for Sake.

Thank you, John!I will continue to study, review and apply the materials.

Emiko Murayama, Tochigi, Japan. (May 2021)

Testimonial: John’s knowledge and most importantly, ability to share that knowledge in a digestible and easy to understand manner, is tremendous. His experience and resume speak for itself but having experienced his method of teaching and passion for sake first-hand has confirmed how great this course is for me. Especially being online, I had lower expectations than an in-person session but the online system is smooth, easy, and we had no hiccups. I learned a ton, feel like my passion and interest for sake has increased 10x and I can’t wait to keep the journey going. Thanks John for taking the time and effort into building the material and for being so open for any questions or concerns during this process and these times.

Brice Burman

I had the honor of taking the Sake Professional Course with Sensei John Gauntner right after passing WSET3. I found this course extremely interactive and gained a deeper and practical appreciation of Sake making and state of the industry as a whole. Sensei John’s knowledge of various breweries and his personal connection made us aware of all the possible variations of Sake making and he instilled a sense of excitement in me to explore Sake more. The class was diverse and global and that made it super interactive as well. Thank you Sensei you shared all your passion and knowledge and made me respect and appreciate the Art of Sake making more.

Mahesh Tirupattur

New to sake? Already a sake-professional? Or maybe you brew it yourself?

Regardless of your current relationship with sake, if you haven’t taken John Gauntner’s Sake Professional Certificate course, you are missing out, so so much.

John covers all the bases of sake making processes, terminologies, and the state of the industry, but fills each lecture with fascinating facts and anecdotes that would only be available through his long-standing and trusted relationship with sake brewers across Japan. These stories make his course unique, captivating, and priceless. For me, it was an eye-opening discovery to learn ways to broaden my sake tasting experience based on the yeast, rice types and the regionality. I deepened my appreciation for sake and the industry, but also grew even more intrigued to explore further into the world of sake. I feel that John’s SPC course gave me a solid compass to confidently navigate through and continue my exploration in the sake world.

I appreciated that this class was offered online and opened the door to over 70 sake enthusiasts from across the globe to participate, without needing to travel to Japan. Although there were missing aspects of not participating in the course in-person (John also made remarks on them periodically), for the accessibility and the quality of the content, the SPC online course is worth every penny and second. I highly recommend it so you won’t miss out on the opportunity.

Akiko Yamagami

To anyone considering taking John Gauntner’s Sake Professional Course:

I am not in the industry but rather an individual who just passionately likes to drink sake and visit Japan whenever I can. So I cannot speak to whether this class would make you a better server or improve your tips as a waiter or let you win salesperson of the month awards. What I can attest to, is if you want to learn as much as possible in an entirely painless way while being constantly entertained and surprised, take this class. Teachers of John’s caliber are very few and far between. His enthusiasm for the subject is an outgrowth of his engaging and caring nature and his depth of knowledge that comes from years of experience. He truly leaves no stone alone. And his goal of wanting to exceed expectations seems a little over-the-top, no? Anyone taking this class already has high hopes to come away with a ton of knowledge. And he wants to top that? Yes he does, and he does. You might think you have a pretty good handle on the world of sake or at least some aspect of it. And yet he consistently amazed me in his ability to broaden and deepen any subject. And not in some arcane way but in a manner that solidifies and expands that base you have.

The course is clearly laid out and it flows easily and understandably from subject to subject. There is plenty of time for questions and discussion and John makes himself unbelievably available during the class. He never treated any question or statement with derision or condescension but with a camaraderie of curiosity. The supporting materials were totally helpful and easy to follow and the final test was well-written, comprehensive and fair. It had none of those jerky gotcha questions from high school. He wants to know if you absorbed the material, not if you can decode a double negative.

If you have an abiding interest in sake and want to go deeper, be entertained a few weekends a month and meet a great person, take this class.

Jeff Wilson-Charles

I wanted to increase my knowledge of sake since we have started selling it in our small restaurant. Before taking John’s Sake Professional Course Level 1 I had very little knowledge of this beverage. John has a tremendous amount of knowledge about sake and Japanese culture and presents it in a way that is easy to understand through his study guides and live presentations. I can confidently say I understand more about the industry and the complexities of sake and am interested in learning much more!

Adam Ogaard

Hands down the most informative sake course ever. If you think that you can just sit through the course and gloss over details, you’re terribly wrong. John Gauntner’s Sake Professional Course is true to its motto of ‘leaving no sake stones unturned’. He really does go the extra mile and depth to impart his knowledge and wisdom on sake. So, be prepared to take lots of notes and learn from the best. Go for it!!

Sayuri Lim

I learned more in a few days with John than in a lifetime of drinking sake. Understanding the intricacies and variations in sake production methods has helped me gain a wider appreciation of the spectrum of sake flavor profiles. The class was not only educational, but highly enjoyable. The class was suitable not only for professionals in the food and beverage industry, but regular people like me who simply enjoy drinking sake.

DC Palter, Los Angeles

Thank you very much John, indeed it was a very enjoyable and enriching experience for me. I didn’t expect to learn so much about Sake and I am genuinely surprised by how well organised your material was. I especially love the way you always have the long answer and the one sentence reply to commonly asked questions and I love how your stories and personal anecdotes on the exceptions to Sake (which are so many). I walk away with my preconceived notions challenged and defeated. Well done and I look forward to when we can travel and meet again for the Advance Course!

Dan Ho

Despite this only being John’s second go at doing the Sake Level 1 online, it was an excellent experience. John’s rich knowledge of the industry shines through with every example, and the course manages a good balance between technical understanding of sake production and colorful stories that bring the industry to life. It seems like COVID has indeed also brought an opportunity to spread sake knowledge more widely through the online format.

Erica Coslor

John Gaunter is one of the most significant bridges between the English and Japanese speaking sake worlds and his course is essential for anyone with a passion for Japan’s national beverage. He communicates the essential knowledge of sake with a lifelong passion and has transitioned his in-person course into a highly effective on-line format. Even as someone who has studied extensively there was lots of new information, delivered in personal style and with a human touch. ’No Sake stone left unturned’ is certainly true; John has a rich seam of experience and anecdote that means no question goes unanswered.

Thank-you once again and I hope to meet in person sometime soon.

Edward Lynch-Bell

I took the sake professional course as a way to get in-depth knowledge of the sake industry beyond the usual historical lesson and tasting information. The course exceeded my expectations by delving into the minute details of sake production,operations of a brewery and even the chemistry behind the brew. In my opinion this is the most information one can get short of doing an apprenticeship in an actual kura.

I hope to take the level II course one day, but being Canadian, I would rather visit Japan when it is not winter.

Thank you, Merci !

Sylvain Frechette

“SPC LO is a wonderful, very informative, and interactive course, in which John engages with all the students and really does leave no stone unturned. His teaching is very knowledgeable and detailed yet he presents it all in a way that people from all sake backgrounds will understand. Having taken other Sake courses I will wholeheartedly say that this was the course in which I appreciated the most, due to the attention to detail and to the class that he gives, as well as the overall first hand experiences he passes onto the students. Also, the fact that we were able to split class into five days rather than two-and-a- half allowed me to absorb the material much better, instead of feeling crammed with time constraints. I recommend this course to both co-workers and friends that also share a love of Sake. A+! Thank you so much John!”

Jared Depry, Portland Oregon

“It has been a privilege to take the SPC LO course with John Gauntner, a true authority in the sake world. If you have a lot of questions, know that he will have all the answers. The course covers general topics about sake, as well as the fine details. I truly and highly recommend it to anyone interested in sake, from beginners like me to advanced connoisseurs, John will keep you engaged from day one until the end.”

Fabricio Romero, Mexico

“If you are looking for an inspirational voice of in-depth knowledge about the sake world in English, John Gaunter’s Sake Professional Course Live Online will disclose those hidden answers behind the rice-based brew. The beauty of this course is that you can do it in any country. That’s the power of having access to this course online! John Gauntner’s course doesn’t stick to just the textbook material, which students receive once they enroll, but his 3-hour lectures consist of real-life examples and understanding of how a sake brewer decides to brew his or her sake. The detail and focus he puts into his lectures are anything but short as nothing is left untold. The fact the conference is via Zoom means that you can participate and ask him questions directly throughout the lecture. I suggest you take John Gaunter course you will never doubt the world of Japanese sake ever again. Arigatou Gozaimasu, John!”

Sandra Gwee, Australia

“If you have any inclination to learn about Japanese sake, you need to take John’s Sake Professional Course. I completed the first fully online version in July 2020 and it exceeded my expectations by a mile. Having lived in Japan in the late ’80s-early 90s and traveled there many times, I have been drinking sake for a while and knew some of the basics. But John’s knowledge of every facet of the sake-making process, it’s history, and the state of the industry today, is truly impressive. John’s course significantly expanded my knowledge & appreciation of nihonshu.”

Rob Grenda, USA

“This course is amazing and more than I ever expected it would be. John is a dedicated teacher and I could not imagine anyone else teaching this course. In my opinion don’t ponder too much on the question “should I or should I not take this course?” Just take it: you will not regret this sake journey.”

José María García Gonzalez, USA

“I joined the first online version of the course and I was really excited. I am a sake sommelier so I had high expectations, but Mr. Gauntner exceeded them and went beyond. His extensive knowledge is inspiring. And most importantly his passion is unbelievable. I think that it’s what impressed me the most. I learned more than I thought and he revived my passion for sake even more. At the end of the course I felt humbled and inspired. I wish I could meet him, and also my ‘classmates’, soon in Japan! Kanpai and thank you so much!”

Giulia Maglio, Tokyo

“My SPC live online experience was 110% positive, and I can’t recommend this course enough to anyone wanting to expand their sake knowledge! I had completed two in- person sake courses prior to SPC (WSET level 3 and JSS’s Sake Academy), but still came

away with tons of new knowledge and insider tips from the industry that only John can provide – his level of personal experience with every facet of the sake world is unparalleled. In addition to the detailed textbook and thoroughly prepared lectures, John took dozens of questions from the group during each session — this forum to be able to ask about absolutely anything sake- related and get a thoughtful answer directly from John was an experience bar none. In fact, it might even work better virtually than in person as people seem less nervous to ask questions online! Even with seemingly straightforward queries, I was surprised by how thoughtfully John responded to each one and added his personal insight to really deepen the level of information delivered and present a new angle on many seemingly straightforward topics. If you are thinking about signing up, all I can say is to take the plunge, you will not regret it!”

Sarah Stewart UK

“John, your passion for the product shines like the North star which makes the course really quite inspiring.”

Steve Peskin, UK

“John Gauntner’s SPC LO was amazing. John is one of the most knowledgeable people I’ve met and is a great instructor! I learned so much and feel much more confident in my sake knowledge. I look forward to doing his Advanced Sake Professional course when it is

available. I’m ready to go out and spread the word to others about the greatness of sake!”

Brian Brill, USA

“It’s been a real joy taking John’s inaugural Sake Professional Course live and online these past few weeks. His knowledge is immense and his passion for sake even larger, it’s contagious. The real benefit here is that as well as all the technical data and factual information, John is able to add relevant stories and recollections from his significant exposure to all layers of the sake world.

As a participant I felt very valued and well looked after. Even though this whole thing was done remotely, you could feel the camaraderie of a bunch of sake fanatics coming together, growing in confidence and knowledge.

I would strongly recommend the course to anyone who has caught the sake bug and wants to accelerate their understanding and appetite further.”

Will Jarvis, Hong Kong

“It has been a complete joy sailing this Sake Professional Course with you – configured with professionalism, executed with ease and scripted in an extremely painless manner. You have triggered in me a lifelong commitment to promoting the word of sake globally that is for sure. Thank you!”

Yegas Naidoo, South Africa

Testimonials for John Gauntner’s Sake Professional Course

(Certified Sake Professional)

“I had certain preconceptions about him and the course. I expected much from the course, and was pleasantly surprised to find that it even exceeded my expectations. John was a superb instructor and the course was wonderful, refining and expanding my existing Sake knowledge. The class was comprehensive, detailed and John added plenty of interesting anecdotes. The tastings were especially compelling, with intriguing comparison tastings that truly assisted you in understanding the complexities and differences within Sake brewing. For anyone seeking a solid and firm knowledge base of Sake, this course receives my strongest recommendation.

Richard Auffrey @ The Passionate Foodie (read more here)

“I went to New York thinking I knew a lot about sake, but after attending John Gauntner’s Sake Professional Course, I realized I had barely scratched the surface. Three days and 100+ sake tastings later, I have a plethora of new knowledge and an even deeper appreciation for sake. From rice varieties to koji to the effects different water has on the final product, every aspect of sake brewing is explored. John is an excellent teacher and communicator, and truly an expert in all things sake. I highly recommend this course for anyone who has a passion for sake. I greatly appreciate the effort and heart John put into making this course a meaningful and worthwhile experience and I can’t wait to further my knowledge in Level 2!”

Karise Murayama

“The mediocre teacher tells. The good teacher explains. The superior teacher demonstrates. The great teacher inspires.” Indeed, John has inspired me throughout my journey learning about sake. Beginning with his book, “Sake’s Hidden Stories” I became fascinated with the attention to detail that goes into making excellent sake. It was a natural progression, then, for me to attend his Sake Professional course and I am so glad I did. It had everything from detailed sake brewing techniques, to extensive sake tastings, to lively discussions of all aspects of sake and the sake industry. If you are serious about sake then you don’t want to miss this course.

Michael G. Emmons, 2009 – App Apps, LLC

“In my role as Director of Education for Fedway Associates Inc., I have completed coursework from the Society of Wine Educators, the Wines and Spirit Education Trust and the Guild of the Sommelier. What do all these institutions lack? A course on sake! Thanks to John, I now have knowledge of all things sake and an incredible resource for information to share with our sales’ force and their customers. Our portfolio includes over ten breweries and sales continue to grow so the need for comprehensive information is vital. It’s not too bad to brag about passing the test either! John’s teaching style is informative and casual but the salient points are clearly

communicated and the handouts are well organized to make presentations easy to assemble. Whether you work in retail, restaurant or distribution, this class is peerless for sake education. Hope to see you in Japan for part 2!”

Gerry Peserchia, 2009 -Fedway Associates

“I wasn’t sure exactly what to expect from this course, but having sat-through as well as taught many wine courses (at all levels), I assumed it’d be similar. I was wrong! Let me explain: the primary reason I began teaching wine (and other beverage) was because, obsessed with wine, I attended many lectures, seminars, etc. Without fail, I witnessed a parade of dry-as toast, droning, wine nerds who, though profoundly knowledgeable, failed to pass ANY knowledge on to their audience. It was as if their goal was to let everyone know how much THEY knew about wine, rather than espousing the goal of passing that knowledge on and creating passion and excitement for fledgling wine folks. Having been familiar with John Gauntner’s “Sake World” for many years (Sake World is a GREAT reference for those looking for a one-source site for all things Sake), I knew that the potential certainly existed for another non-learning experience. I could not have been more wrong. John’s course was evenly-paced, intense, challenging and entertaining! He covers Sake in a “soup to nuts” fashion, without becoming mired in the minutiae (which I’m certain …and hopeful…will come with the second level). John CLEARLY demonstrated his deep level of Sake knowledge, but filtered the information in a manner that inspired, rather than intimidated, an amateur like me. Being on the wholesale side of the beverage business, my wine knowledge has only rare application in day-to-day calls. Because of John’s course, however, I’ve already found that a working knowledge of Sake has huge benefits in everyday sales conversations! So far, there is nothing I learned in John’s course that I’ve been unable to use, if needed, in the streets. For those, either in the beverage industry or aspiring to be in the industry, this course IS A “MUST”.

Tim Hirota – Southern Wine and Spirits

“If you are ready to take the next step in your fascination and love of sake the only way to go is up with John Gauntner. Consider the professional sake tasting course a graduate education as you explore the essence of sake from such an elevated perspective. This course tied in a perfect blend of understanding, appreciation and sheer fascination. Sake is indeed and art form and the professional sake tasting program provided me the proverbial ability to “pull the curtain back on the wizard” in terms of understanding the nuances and quirks that make this industry what it is. Whether you are a beginner or self-taught junky the SPC provides you the rarest of all perspectives on the inner-workings of an age-old profession that is exploding onto the global stage. John Gauntner is a once-in-a-lifetime tour guide and professor wrapped up in an enjoyable and personable package. In a word the professional sake tasting program is purely ‘enjoyable’ and an experience that will energize you for the rest of your life.”

Beau Timken, 2003 – Owner/operator of True Sake

“As a producer of an alcohol-focused, educational television program, it was imperative that I gain as much information about the subject of sake’ as possible. My initial approach to learning this art was to gain knowledge by working in a sake’ brewery in Japan for the 2009 sake’ season. Once I completed my brewing internship program, I found that I was capable of producing one style of sake. However, I was not fully educated in the variety of the many different styles, regions, history or the nuances of the business industry as a whole. After partaking in John Gauntners’ Sake’ Professional Course, where he passionately touts that “No sake’ stone left unturned” I realized he was not overstating. During this extensive and intensive course, there was truly “no Sake’ stone unturned.” I feel with this program, together with my time brewing in Japan, I am well rounded in this subject matter and find that John’s course will serve me well whether I use the knowledge for TV production, importation, sales or brewing.”

Richard Gummoe, 2009 –Executive Producer, Boy Meets Still TV

“What differentiates a great teacher from an average one is an innate and developed ability to balance fact with nuance. In his course, John displayed tremendous precision of thought supported by a nuanced and granular understanding of the global sake industry. John is a thought leader in the sake industry supported by his in-depth knowledge of the industry, access to a wide and deep network of industry professionals, and a lucid understanding of when the answer to a sake-related question is “It Depends” and when it is black and white. John’s class is a well designed thoughtful class that can serve as a solid building block for someone interested in getting involved in the sake industry.”

Akshay Shetty, 2009 – New York

“The Sake Professional Course is excellent because it covers both the theory and tasting of sake in excruciating detail. The material and class is organized very well which allowed me to dramatically increase my knowledge of sake in just 3 days of lectures. John also does a great job of injecting life into the material as well with industry stories & nuances that you would not be able to simply find in a book. One of the absolute highlights of the class is also how well the tastings are broken down. Tastings hundreds of different sakes without any organization over 3 days would just feel chaotic; however John does an excellent job of breaking them down in logical and thematic segments. This allowed me to really develop or train my palate to be able to taste everything from different rice types to regionally. If you really are interested in improved your theoretical sake knowledge and to begin learning how to taste sakes I highly recommend this class.”

Ben Neidhart

“In June of 2010 I had the distinct pleasure of taking John Gauntner’s Sake Professional Level 1 Course in San Francisco. We were promised “no sake stone left unturned,” and John-sensei more than lived up to his word. The course was a very intense 3-day journey into everything sake, from harvesting of the rice through every step of the processing, to bottling, shipping, tasting, and enjoying. Throughout the course John-sensei’s incredible in-depth knowledge and passion for the subject kept our attention and made the course interesting and exciting. The three days went by too quickly, and I was very sad when it was over. Before taking the class I had read several books about sake and had even ordered and studied John-sensei’s educational products from his Sake World web site. I wondered if I had anything else to learn that I didn’t already know. But reading and self-study only goes so far. John sensei’s insider knowledge gained from years of experience of being intimately involved in the sake industry in Japan add so much life and detail not available in any books, resulting in it being well worth the time and effort to take the Sake Professional Course. I’m hoping to take the Level 2 class when it’s offered next year. If you want to learn absolutely everything there is to know about sake, whether it be for business reasons or personal interest, I heartily recommend taking John Gauntner’s Sake Professional Course. It’s time well-spent on a fascinating subject taught by the foremost authority on all things sake.”

Carl T. Geenen

The Sake Professional Course is really one of a kind. John keeps everyone engaged and excited during his talk – from one hour to up to a 5-day course. I have not seen anyone who can inspire so many people as John does with his genuine passion and knowledge. If you have even the slightest interest in sake then this course is definitely worth taking. John has contributed so much to the upward trend of sake around the globe by sharing his knowledge of sake and the industry both in Japan and abroad. Thank you, Gauntner-sensei!

Etsuko Nakamura

Founder – Sake Tours

“I took the Sake Professional Course in NYC in summer of ’09. The course was thorough and fun with many of his interesting personal experiences in the Japan’s sake world. I was amazed with not only John’s extensive knowledge of sake but also his knowledge of Japanese culture, geography and history to go along with it. (He is more Japanese than I am!) Broad selections of sake were offered for tasting in the class to understand the differences of all kinds which I have never been able to experience before. Another thing to mention was his passion of teaching. He was always attentive to anyone’s questions in very approachable and kind manner. No questions were unanswered. I enjoyed the course very much. I would strongly recommend this course to anyone who is interested in learning about sake in depth. Looking forward to taking level 2 in Japan as soon as it becomes available.”

Iori Kataoka , 2009

Shuraku Sake Bar and Bistro / Zest Japanese Cuisine, Vancouver B.C. Canada

“No sake stone left unturned is the perfect description for this course. John goes into great depth and covers all of the intricacies that make up the wonderful ambrosia that is sake. Everyone who is lucky enough to take this course will leave it feeling that they are among a handful of people in the United States and around the world that have a real understanding of all the many facets that make up sake. John keeps the material interesting for both total sake neophytes as well as those who have a more advanced understanding of sake. John’s manner is approachable and open and his teaching style is clear, and he is able to make even the most mundane facts interesting. I highly recommend this course to anyone wanting to explore the world of sake.”

Blake Spahn, 2009

CEO, Ty Ku

“John’s method of teaching both the “short answer” and the more “technically advanced” covers all ranges of people who one may be trying to educate. There is nothing in the Sake World that John does speak of. It is as comprehensive in the history, to brewing process, to culture, and to the tastings of almost 100 different Sakes that could not even imagine is paralleled. I highly recommend John’s class no matter your Sake knowledge. You will learn, be entertained, and come out with a great understanding that Sake needs to be promoted to rid of the misconceptions and to clear the mystery behind this ancient beverage.”

Avery Martin, 2009 -New York

John’s course is essential for anyone that is truly passionate about sake. It is the necessary well rounded education on a topic that appears simple yet has so many underlying complexities that are necessary to understand for true appreciation. The course simplifies complex processes and pieces things together in a very cogent way that allows even the layman the ability to wrap their head around the topic. While the course goes in depth on the brewing process what is truly fascinating are the anecdotes used and historical facts that tie the topics together and keep the subject matter fresh and relevant. I thoroughly enjoyed the class and would recommend it to anyone.”

Kirk Spahn, 2009

“The Sake Professional Course was extremely worthwhile and informative. An A to Z of sake. John is a first rate instructor; both his passion and knowledge are consistently conveyed throughout the course. The material is very well organized and approachable, yet sufficiently in depth. This is a “must attend” for anyone who wants to really understand sake.”

Andrew T. Chrisomalis, 2009

“The Sake professional Course covered all aspects of sake, from brewing to tasting and provided the context for understanding the geographic variations of sake. John Gauntner is a superb lecturer who makes the subject of sake fascinating for all.”

Mary Goetter, 2009

“I had the good fortune of taking the Sake Professionals’ Course because the distribution company that I work for had the opportunity to send 1 person to the course because of our relationship with TYKU. Before taking the course I knew nothing about sake, beyond knowing that I enjoyed drinking it. The course not only demystified sake, but in fact I now feel as if I can hold an engaging high level conversation on the subject. Being a bit of a wine geek, I appreciated the high technical level of the course, particularly in reference to the production methodology and some of the chemistry, etc. Also, because the students were generally more advanced than I in their sake studies, I very much enjoyed and appreciated the fast pace of the class. I feel I learned an incredible amount and am so excited to continue to drink sake and expand my experience with sake.”

Jordan Lari, 2009

Empire Merchants

“John Gauntner’s sake course is surely the most comprehensive available. For anyone wanting to learn everything there is to know this is the course for you!”

Brad Paddock

Rock Sake

“Just back from three days of Sake study, tastings and discussions that reinforced many points, answered numerous unanswered questions and gave plenty of fuel to help me continue to spread the love for premium sakes. John’s depth and breadth of knowledge knows no bounds and he has this uncanny ability to capture all of us from all levels and backgrounds and in a very short period of time be able speak to all on the same level. An excellent program that I wouldn’t hesitate recommending to anyone, whether an industry professional or an interested consumer who wants to fuel their sake passion!”

Patrick Ellis

Blue Note Wine & Spirits Inc.

” ***** out of five!” I laughed, I cried, I drank sake until it came out of my ears! John Gauntner’s sake professional course is unlike anything else out there, a delicious and intensely focused, yet thoroughly enjoyable exploration into the world of sake. I came away with a far deeper appreciation, not just for sake, but for Japanese culture and cuisine as well. Highly recommended.”

Todd Eng, 2007

Owner-operator of soon-to-be-opened sake pub in SF

“Thank you for your dedication to the sake world in general. I thoroughly enjoyed your class, and received great benefits from the knowledge I was able the gain through your course. I knew very little about sake starting your course but grew a “love” and appreciation for this obscure beverage. Even as I write this, I just got done tasting sake from one of our vendors, and was able to distinguish between what he was selling me and what I knew (for sure) from taking your class. In other words I was now informed and was able to make an intelligent choice based on the knowledge gleamed from your course. This course was invaluable to me. On a personal note I am able to enjoy Asian cuisine (sushi, Thai, Chinese, etc.) paired with a sake of my choice, which enhances my dining experience.”

Robert Perry

GM-Khotan at Treasure Island

“Thank you very much! I can’t tell you how much I appreciated taking your course. As I said before, I really respect your style of teaching. The manual was very thorough. Your lecture was replete with brewery stories which put the technical data in perspective. Your explanations were very clear as you guided us from simple to complex. The comparative tastings perfectly solidified my understanding of the subject matter. It’s one thing to learn about sake, it’s another to experience what was just learned. I have always taught people that the best way to learn about wine is to read and taste. I look forward to taking SPC 2. Thank you very much for allowing me to begin my journey in this wonderful world. On a side note, I have earnestly begun experimenting with non-Japanese food and sake pairings. I am enjoying the umami-to-umami (U2U) connection.”

Jonathan Davis, Las Vegas, 2009

Southern Wine and Spirits, Las Vegas

“I was exposed to premium sake 25 yrs. ago by a Japanese sushi chef, who taught me the correct way to eat and enjoy all Japanese food. He would occasionally get a bottle brought to him by someone returning from Japan. Nobu-San would share and explain what I was having but it was confusing and a little hard to understand. I now work in a wine store owned by two Master Sommeliers. We have always been a leading edge kind of store and started carrying premium sake almost ten years ago. We stumbled through learning what we could from some articles and suppliers info until we became aware of your book and subsequently your enthusiasm for sake. One of the owners has taken your course in New York and two courses in Japan; her enthusiasm has driven our sales and an ever expanding selection of sake. I attended the class with the other owner so that we could begin to keep up with Sally. The way you presented the vast array of information in a clean and logical order opened my eyes to so much I had taken for granted. Sake is liquid art and as such is very subjective, however understanding the history, materials and techniques can make for a much more gratifying experience. As the buyer for the store I now have the ability and desire to choose and present a broader and more interesting selection of sake’s and to educate and inform our customers to another interesting and exciting beverage choice. Domo! Sensei!!”

Jeff Mathews, 2009

The Boulder Wine Merchant

“The course was great! John was his usual fountain of sake knowledge when teaching. The 90 or so bottles we tasted covered a wide range of styles, rices, yeasts, ages, etc. There is certainly no better opportunity in the US to taste and evaluate such a collection with such all-star instruction. Overall it was a great experience – highly recommended for anyone interested in sake.”

Wayne Belding, 2009

The Boulder Wine Merchant

“This is an excellent and comprehensive class on sake. I don’t think there was a “stone unturned” or a question un-answered, and the tastings were some of the most thoughtful I have ever encountered in the wine/sake/beverage business. We compared rice varietals, yeast strains, regions, pressing techniques, temperature differences, and quality levels, and the sakes chosen for these tastings demonstrated the differences and made sense. John is an amazing teacher, and does a great job of explaining a very complicated beverage in understandable steps. I recommend this class to anyone interested in sake, regardless of their profession. Very inspiring and eye-opening!”

Morgan Hartman, 2009

Vine Connections LLC

”Having the unique opportunity to learn about sake from John was truly enjoyable and memorable. The amount of knowledge he has gathered over the years in a field that is not so easy to access, especially for non-Japanese, is amazing. I highly recommend taking this intense course if you are in any way interested in sake. Tastings are also very well done, always with a very specific purpose, whether to showcase regional styles, sake rice types, even serving temperatures and vessels. It was great to taste almost 100 sakes in three days, especially those that are impossible to find in the US. This enriching experience was hard to beat and I am certain my sake program with over 120 labels will immensely benefit from it.”

Dieter Xiao, 2009

General Manager, Shibuya Restaurant, MGM Grand Las Vegas

“One with the lot! John Gauntner’s Sake Professional Course is the one stop, be-all and end all, look no further, insight into the world of sake. From the basics through to the nitty gritty,all points are covered and it’s one hell of a ride. During the first section of the course, each day participants are skillfully guided through the tastings and technical in the classroom, then masterfully unleashed into the world of izakayas and sake bars at night to put their newfound knowledge to the test. John is always there for you, with his limitless knowledge and unyielding passion for one of the world’s great drinks. His expertly prepared class notes, extensive tasting hints and well considered evening haunts make this course a must do for anyone who has more than passing interest in sake. The excursions into the world of sake brewing and the kura visits are worth their weight in gold, an experience you would not be able to enjoy by any other means.”

Andre Bishop, 2007

Owner, Izakaya Chuji Japanese Restaurant Chain, Melbourne, Australia

“I am the gallery manager for Lesley Kehoe Galleries, dealers in fine Japanese works of art. In January 2007 I was fortunate enough to attend the sake professional course in Tokyo. The course was a thorough and enlightened introduction to the many guises of Nihonshu. Unlike many of the attendees, I am not involved professionally in the beverage industry however this was no barrier to John presenting a clear and balanced presentation of the available information. The range of sake on tasting was extensive and represented a huge variety of styles. I came away from the course on massive high and would not hesitate in recommending this course. Become a 酒人(sake person)!!”

Trevor Fleming

Lesley Kehoe Galleries, Australia

“If you’ve been bitten by that alluring sake bug like I was ten years ago, and you want to take a deeper dive into this “drink of the gods” for your professional development or purely as a personal quest, take John Gauntner’s Sake Professional Course. As an avid sake enthusiast and restaurateur, I found tremendous value in this course. Over the intensive course, John will guide you through an engaging tour of this wonderful beverage that is as complex and fascinating as wine – – from the history and tradition thousands of years old, to visits to modern day sake brewers where you will have the privilege of seeing the brewing process in action. The “classroom” education is reinforced by tastings of numerous sakes. John’s anecdotes and stories, collected over decades of his immersion in the sake world, add vivid texture to the course. And of course, it is sake after all, so your fellow classmates are pretty much guaranteed to be fun and come from a host of interesting backgrounds. If you like sake, love sake, want to learn about it for your professional or personal development, or even have a slight interest in digging deeper than admiring those beautiful labels, take the Sake Professional Course.”

Nancy Cushman, 2006

Proprietor & Sake Sommelier of O Ya Restaurant in Boston, MA

“I thought I already knew a lot about sake. I was wrong. We tasted many amazing sakes not available in Canada, and many that were brought in from Japan. Mr. Gauntner’s articulate lectures were very enjoyable, and he delighted us with many anecdotal moments from his experiences in Japan. John Gauntner’s course mantra is ‘Leave no sake stone unturned’. It was indeed enlightening to know that what I knew was the equivalent of a grain of sand’. Thanks John!”

Michael Tremblay

Event Coordinator, ki modern japanese + bar

“Considering whether to take John Gauntner’s Sake Professional Course is a no brainer. When you complete the course, you’ll be a sake aficionado schooled by one of the great sake experts in the world, who’ll have personally guided you through numerous tastings and brewery tours in Japan. It’s a unique opportunity not to be missed by anyone with a keen interest in sake. John’s passion for sake is evident in his books and articles, which are wonderfully written and informative, but they’re nothing compared to being in the same room listening to this guy talk. From the basics of how sake is made, to the nitty-gritty of yeast strains, to his many enjoyable

sake anecdotes and observations, John’s enthusiasm is palpable and inspiring. It was remarkable to meet others–from different countries and walks of life–and bond via our mutual love of sake. It made me realize just how far-reaching this drink’s popularity and influence has spread outside of Japan. The course allowed me to truly understand, by seeing first-hand, the depth of tradition and care that goes into the craft of sake-making, which has only further enhanced my interest and appreciation for nihonshu.”

Elise Gee, 2006

Sake Educator

“Hiroko and I couldn’t have had a more thorough immersion in all aspects of sake than that which we experienced at with the SPC this past January in Tokyo. I can’t imagine how any course on sake could have been more comprehensive and, equally important was that the material was presented in the most articulate, easily understandable and absorbable fashion…not so easy for a subject fraught with complexity and inextricably intertwined with thousands of years of Japanese culture. This is THE definitive course of study for anyone who is passionate about sake and/or involved with serving or selling it. We cannot thank you enough for giving us

the foundation necessary to launch our shop in NYC!”

Rick Smith & Hiroko Furukawa, 2007

Sakaya…New York’s first shop specializing in sake

“What a lucky person who has the opportunity to meet the Sakeguy! John Gauntner is extremely well versed in all aspects of Nihon-shu, the national beverage of Japan. His presentations, tastings, courses, as well as books and numerous articles attest to a lifelong commitment and love of all things Sake. If you have a desire to know more about this exquisite elixir; John can de-mystify, add clarity and enhance your appreciation. He is an excellent teacher, never a dull minute, and well worth twice the price for all that is imparted in any of his educational venues. The Professional Course brings together all aspects of Sake. It is presented in a simple, logical and straightforward manner. A beginner is not befuddled, and the more seasoned Sake aficionado is not left wanting. All material is well presented, made interesting to professionals in the field and laymen alike.

I found his Level I Course to meet my needs. Being of a long-time resident of Japan, but non-fluent in Japanese, socially engaged, but not as knowledgeable about my now first preferred alcoholic beverage. I am now very comfortable hosting my Sake parties, and speaking about Sake with more authority than I had before.I most highly recommend this course to anyone having more than a passing interest in Sake as a beverage and to gain insight into one theme in the Japanese way of life.”

Mike Brenyo, D.D.S., Las Vegas 2009

Yokosuka Japan

“John’s course is a must for anyone interested in sake. I strongly suggest getting in as soon as possible because the interest in sake and John’s classes get’s bigger every year. His approach to teaching the ways of sake is down to earth and very comprehensive. I use what I have learned on a daily basis with my staff and clientele. It was an honor to be in the presence of someone so knowledgeable and so humble. It is easy to see why the Japanese sake community loves him so. I look forward to taking the advanced class in February of 2008. Thank you John for being a wonderful sensei and a hell of a guy.”

David A. Roth, 2007

General Manager Koji -Yakitori – Sake – Bar, Hartford CT.

“John Gauntner’s “Professional Sake Course” was a fabulous learning and tasting experience. His deep knowledge, passion and understanding of sake (in all its beautiful vagueness) is evident to all who take his course. John’s intention to “leave no sake stone unturned” over the three days of intensive study and tasting exceeded expectations. The sake industry, hotel and restaurant professionals in attendance conveyed to me the level of talent seeking out John’s take on the world of sake.”

Phil Heyser, Las Vegas 2009 CS, SSI

“The saki course was great and anyone who is passionate about saki or in the industry will strongly benefit from the course. Except for your books finding good solid info about saki for the English speaker can be a difficult task. The course not only sheds light on all the ins and outs of saki production from the grain to the bottle but also has numerous tastings designed between/after the lessons. We tasted over 90 sakis in three days and this really helped me open my mind to the different flavors and possibilities in the world of saki. The course itself is very well organized; you also receive a great handbook with all the info from the lessons. John is a good and patient teacher, who takes time for all students’ questions and is thorough in his explanations. If it’s saki you’re into, there is no better place to go. Kampai.”

Michael Opalenski, 2009

B. United

“In the world of sake, understanding the dynamics can seem vague and obscure. Sake, unlike other forms of alcohol, is a process that not many are capable of explaining because it is far more complex than most. John has the unique ability to uncover the veil of the sake world as he guides us through the lose translation and dimensions of the process itself. The course not only goes in depth regarding the fundamentals of sake, it also teaches you to use your senses to guide you through understanding the various types of sakes there are and the history behind them. The experience not only left no stone unturned, but generated the stepping stones I needed to become a better success at my workplace as well as build the confidence to better educate and understand a trade that I’ve grown to love. Taking this course is like traveling to a far off country to understand its culture you never come back as the same person. With that said, I look forward to experiencing taking level 2 in Japan.”

Bernadette Stanton, Las Vegas 2009

Sake specialist at Hachi, Red Rock Resort, Las Vegas

“Just wanted to let you know how fantastic I thought the Sake Professional Course was. The tastings were first-class; I’d never seen so many different types of sake all together in one place before. I didn’t expect to have so many sake to taste and study and was pleasantly surprised. The instruction was clear and easy to follow. Everything was presented in a logical order and was great for someone who knew absolutely nothing about sake. As a sommelier and bartending instructor everything I learned is really going to take my career to the next level and help me offer something totally unique to my students and clients! Thanks John! Looking forward to Level II.”

Kristy Koehler

Vancouver, Canada

“Having lived in Japan for more than 25 years I remember John’s first sake articles in the English language newspaper. Long before all the world’s information became “google-able” I patiently waited each sake article. I remember thinking, “This man is interpreting the ‘Rosetta stone’ of sake”! He is making perfect sense of the hieroglyphics on sake labels and installment after installment he is explaining the intricacies of a product whose sophistication I so appreciated, but could not easily articulate. John’s books were added to the newspaper clippings. And as I prepared to leave Japan and return to my native New York it was John’s writings that made me eager to learn even more and become part of the niche of sake lovers and sake professionals. When I heard of the Sake Professional Course I could not resist. John breathed life and a fiery passion into all the words in his articles and books. The pace of the class demanded one’s full attention. And taste buds needed to be set at Orange Alert so as not to miss the subtle nuances of the awesome selection of fine sake John prepared for us to taste. I was able to parlay 25 years of professional experience in Japan and the invaluable lessons of the Sake Professional Course to secure a wonderful job in the trade. And I refer to the text and to John whenever I have a question. In Japan they say that it is rude for a student to “praise” a teacher. So I will paraphrase a Buddhist teaching.“I rely on the teacher; the teacher relies on me” Meaning that just I relied on the excellence that I knew the teacher would bring to the course. I want John to be able to rely on me, his student to disseminate correct information and maintain the integrity, passion and joy of sake he so generously shared with all of us in his Sake Professional Course. I am forever indebted.”

Linda Noel Kawabata

USA Brand Manager Akita Sake Promotion and Export Council

“Sam Calagione, the founder of Dogfish Head Breweries once said, “The only teachers worth listening to are those who realize that you might have something to teach them, too.” John is one of these great teachers, his passion for sake is amazing and infectious, and his array of accumulated knowledge is vast. He remains approachable and open-minded which ensures that he and his students always keep learning and having fun. The best way to learn is to do; the course embodies this spirit and is not only a way to receive a formal sake education, but perhaps the only real way to receive a genuine understanding of the subject.”

Yoed Anis, June 2010

Austin Texas

“The three day Level I Sake Professional Course intensive was exactly that, intense! I had no idea there was so much depth and detail concerning the production and brewing of sake. I have been in the Food and Beverage Industry for over 10 years. I have spent most of that time in New York City and Las Vegas as a bartender, but I have never been exposed to or needed to learn about the world of Sake. I was just awarded my Certified Specialist of Spirits in July of 2009 and promoted to Master Mixologist of MGM Grand Hotel and Casino, yet still no exposure to sake, until your course. I found your understanding and depth of knowledge to be remarkable.

Likewise, your course material and approach to teaching, while probably not for the novice enthusiast, was very comprehendible for the Beverage Professional student. I found myself not only learning, but becoming excited about this new found knowledge. As we progressed through the material and days I started making the connections within the process and found myself less bogged down by the language barrier. In short, it all started making sense. I was amazed at how much knowledge could be attained in the allotted amount of time. Apart from the classroom material, I had never been exposed to the number and styles of sake in the tasting module. I appreciate the structure of the daily tasting as each one focused on a specific theme. We had geographical tasting, rice varietals tasting, quality difference tasting, and vintage tasting and as we moved through each one you not only gained appreciation for the different styles, but you also began to understand the difference and impact of each decision in the brewing process.

All together, as a professional in the industry, I found this course invaluable at increasing my knowledge and comfort with a product that up until now was completely foreign to me. I now feel effective at recommending sake to our guests and being able to decipher any sake label. I would like to thank John for his passion and tireless devotion to his craft. To openly offer your knowledge and expertise to others is a tremendously humbling gift. Repeatedly throughout the course John expressed how each of us “own him” now, but I think that is a reciprocal feeling. It is all of our responsibility to spread the knowledge and passion John has been so kind to impart and therefore he “owns” a team of ambassadors around the world. In closing, I would recommend this class to all industry professionals as well as any sake enthusiast.

Kent Bearden, CSS Las Vegas, Nevada, USA

Master Mixologist, MGM Grand Hotel

“Thanks for being the best guide possible into the realm of Sake. You are an engaging presenter and an expert from whom I learned a ton. I was a hundred percent impressed with the course experience.”

Kenneth Stutz – Piedmont, CA

Stutz Company Inc.

“I thoroughly enjoyed the Sake Professional Course with you in San Francisco, this summer. I knew that I had absorbed a great deal of information during the tastings and lectures, but was pleased with how events unfolded on my return. I arrived back to the heat of Dallas and was a guest at a going away party for one of our Aikido instructors. I was promptly given the sake menu at the sushi restaurant and admonished to pick good sake for the group! I was obviously being put on the spot (they knew where I had been!) and the pressure was on to perform. I was pleased to be able to look at the sake selection of around 10 sakes and recognize each one. I was able to answer the group’s questions and select a few bottles to meet everyone’s tastes (we decided on the Tokubetsu Junmai (high milling rate of a ginjo), the Dai Ginjo and the Nigori sake). Everyone was pleased with the selections and I left feeling that my time and money with you had been well spent. I look forward to returning to Japan and joining you for the brewery tour and level two class!”

Dr. Nick Chamberlain, June, 2010

Chamberlain Studios of Self Defense

Dallas, TX

“I participated in John Gauntner’s Sake Professional Course January 2006. In my perception, this is the best way for a non Japanese speaker to get a proper understanding of sake, and I would strongly recommend anyone with a dedicated interest in sake to take this course. It is however, important to take the whole course, including the visits to the various breweries, as this gives a broader understanding of the cultural and technical aspects of sake and sake brewing. The 5 days of which my course took place, was extremely tiring, as the day’s itinerary was packed. This is however a good thing, as I felt I did nothing but living, thinking and doing sake for 5 days.

I cannot write about this course, without mentioning the dinners which followed every day’s classes. This included everything from restaurants to Izakayas where the meals, the sake and the atmosphere were absolutely wonderful.”

Kjetil Jikiun, 2006

Head Brewer, Nogne O, Det Kompromisslose Bryggeri AS, Norway

”If you are looking to enhance your knowledge on sake and experience first hand all that you need to possibly learn and taste, this course has it all…and much more! John made sure all the critical points on sake brewing and more were extensively covered during the course and was extremely accommodating in fielding the numerous questions thrown his way. The ultimate professional!”

Les Pung

Elk Grove CA

“Everyone can learn from John’s course — from home brewers to bar managers to distributor professionals. The course is well structured and covers everything from the core basics to a detailed exploration of the production process, which is critical if you want to educate others about the intricacies of Japanese sake. Advanced topics include issues that you can find very little about, including slow brewing yeast starters, the chemistry of sake and a look at the regional variations across the country. Tasting is a key component of the course and John does

an excellent job of selecting sakes to demonstrate key points throughout the course. I wouldn’t hesitate recommending this course to anyone interested in sake. John is sincere in that he wants to create a network of people who can educate the world about sake and dispel many of the myths that have held the category from gaining widespread acceptance in the mainstream market.

Jim Andrews

Founder/CEO, Wasabe Beverages Inc

John’s course was fun and informative! He definitely knows his sake and consequently, now so do I.

Craig Dahlberg, 2009

moto-i in Minneapolis

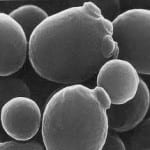

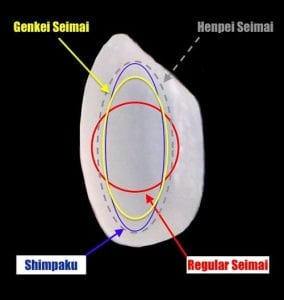

In just about any educational material about sake, we read or hear that the main difference between premium grades of sake like ginjo-shu and regular non-premium sake is the milling of the rice. Specifically, for ginjo sake the rice has been milled much more, and down to a specified degree before brewing. The more the rice is milled, the higher the grade of sake. Short and sweet, and easy to remember. Yeppir.

In just about any educational material about sake, we read or hear that the main difference between premium grades of sake like ginjo-shu and regular non-premium sake is the milling of the rice. Specifically, for ginjo sake the rice has been milled much more, and down to a specified degree before brewing. The more the rice is milled, the higher the grade of sake. Short and sweet, and easy to remember. Yeppir. The next Sake Professional Course will be held in Miami, Florida in September.

The next Sake Professional Course will be held in Miami, Florida in September.

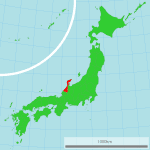

I do not get to Ishikawa Prefecture often enough. It sits nestled basking in its historical glory, on the Japan Sea side of the country, its rich history former reputation for wealth and opulence in stark contrast to mellowness and sleepiness that pervades much of the prefecture today.

I do not get to Ishikawa Prefecture often enough. It sits nestled basking in its historical glory, on the Japan Sea side of the country, its rich history former reputation for wealth and opulence in stark contrast to mellowness and sleepiness that pervades much of the prefecture today. eighty percent water, it exerts massive leverage on the nature of the final sake. And while iron and manganese need to be at very low levels to even begin to think about using a water source for making sake, beyond that brewers discuss the hardness or softness of water. This is measured by the amount of magnesium and calcium or calcium carbonate.

eighty percent water, it exerts massive leverage on the nature of the final sake. And while iron and manganese need to be at very low levels to even begin to think about using a water source for making sake, beyond that brewers discuss the hardness or softness of water. This is measured by the amount of magnesium and calcium or calcium carbonate. Bear in mind that when making sake, the first milestone is the moto – the yeast starter – which takes two to four weeks to prepare, and the goal of the moto is to have a mini-batch with an extremely high populations of healthy, strong yeast. After that, more ingredients are added in three stages, roughly doubling the size of the batch with each addition, and then fermented for an additional three to five weeks, with the goal this time being more alcohol, and enjoyable flavors and aromas of course. This longer fermentation is often carried out at lower temperatures, and much more slowly, as such conditions encourage cleaner and more aromatic sake.

Bear in mind that when making sake, the first milestone is the moto – the yeast starter – which takes two to four weeks to prepare, and the goal of the moto is to have a mini-batch with an extremely high populations of healthy, strong yeast. After that, more ingredients are added in three stages, roughly doubling the size of the batch with each addition, and then fermented for an additional three to five weeks, with the goal this time being more alcohol, and enjoyable flavors and aromas of course. This longer fermentation is often carried out at lower temperatures, and much more slowly, as such conditions encourage cleaner and more aromatic sake.