Listing Rice Varieties on Labels …and the attendant hassles

There are about a hundred different types of sake rice used in making sake. About. But not all sake is made from shuzo-kotekimai, or proper sake rice. Most, in fact is not. But almost all premium sake is. And of that hundred, about a dozen are commonly seen and important. Add to that another several dozen varieties that are not proper sake rice but suffice well enough to be used in brewing decent sake.

There are about a hundred different types of sake rice used in making sake. About. But not all sake is made from shuzo-kotekimai, or proper sake rice. Most, in fact is not. But almost all premium sake is. And of that hundred, about a dozen are commonly seen and important. Add to that another several dozen varieties that are not proper sake rice but suffice well enough to be used in brewing decent sake.

However, sake brewers are not obligated to tell you which rice was used in a given sake. No one really hides it. It is just that from a marketing perspective, it had long been considered superfluous information. It is not really that way anymore, especially in top-grade sake. The rice is indeed important!

The other side of that coin is that, although they are not obligated to tell you the rice, if they want to do so there are rules and regulations about what can in fact be listed. As a quick example belying a Pandora’s Box of vagaries and issues, they can use a perfectly good rice grown locally, but if the local agricultural co-op has not agreed to register and inspect that rice for local production, the name cannot be listed on the label. But let’s back gingerly away from that chasm of a diversion, at least for now.

Let us look instead at another aspect of sake labeling. In short, if a producer chooses to list the rice on the label, they must also list what percentage of the total rice in that batch corresponds to that rice. For example, “made using 100% Omachi,” or “75% Miyama Nishiki and 25% Yamada Nishiki.” The point and reasoning is to prevent a brewer from making a tank using some schlock rice and lobbing one grain of superb Yamada Nishiki in there, and then bragging on the label, “made using Yamada Nishiki!” Not that anyone would really do this. But you know…

Let us look instead at another aspect of sake labeling. In short, if a producer chooses to list the rice on the label, they must also list what percentage of the total rice in that batch corresponds to that rice. For example, “made using 100% Omachi,” or “75% Miyama Nishiki and 25% Yamada Nishiki.” The point and reasoning is to prevent a brewer from making a tank using some schlock rice and lobbing one grain of superb Yamada Nishiki in there, and then bragging on the label, “made using Yamada Nishiki!” Not that anyone would really do this. But you know…

Also, generally speaking, the blending of rice in a single batch of sake is not common. It is much more commonly seen than it used to be, but still it is not common. Why not? Because different rice types behave differently, they dissolve and break down and make their mark in different ways. If you have two rice types doing their thing together in one batch, predictability suffers. Heck, any one rice type behaves differently each year – and even from batch to batch in a single season! Many brewers feel they are unnecessarily complicating matters if they use more than one type in a given tank. Again; it is not unheard of, just not common.

And when we do come across more than one rice used, it is most common that one (the superior) rice is used for the 25 percent or so of the total rice that is made into koji, and another (lesser) type for the remaining 75 percent that is straight steamed rice added to the batch. So a 25/75 split amongst two rice types is something we do see from time to time on labels.

And that is the point here: that whatever the brewers choose to use, if they choose to tell us, they must document it properly on the label. But then, there are problems related to the fact that rice is an agricultural product subject to the laws of Mother Nature, who does not bother to check with brewers about their plans for the upcoming year. Nor does she seek approval for weather patterns. As such, from time to time shortages exist (for other reasons too, like demand) and brewers do not always get what they ordered, or when they ordered it.

This fact can cause hassles for brewers when they choose to list the rice on the label.

Quickly summarizing the issue, let’s say a brewer makes ten tanks of a given sake, and the very last one of those ten was partially made with a rice different from the rest because “what was ordered did not come in.” When those ten are blended for consistency across that year’s product, the entire batch becomes “tainted” with the one single one made even partially with a different rice.

Will this perceptibly affect quality or flavor? No. Of course not. But the brewer would still be legally obligated to note this on the label, with something like “99.5 percent rice A and 0.5 percent rice B.”

I had this complaint vociferously explained to me by an ornery brewer a few years ago, a conversation I documented here . Yet, I had never once seen a real-life example of such confusing labeling. So, I assumed, the problem exists in theory alone. Until now.

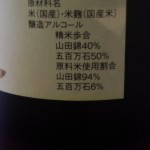

A couple of weeks ago I was visiting a brewer in the historically as well as currently significant Aizu-Wakamatsu region of Fukushima Prefecture. And while tasting their lineup, I spun the bottle to see the gory details on the back label. And there it was.

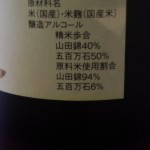

It read: “Yamada Nishiki: 94%, Gohyakumangoku: 6%”

The natural reaction would be, why would anyone do that? Why would a brewer use 94 percent of one rice, and but 6 of another? The answer was clear: the rice wasn’t available. But it played out a bit differently than I had thought it would.

The natural reaction would be, why would anyone do that? Why would a brewer use 94 percent of one rice, and but 6 of another? The answer was clear: the rice wasn’t available. But it played out a bit differently than I had thought it would.

Upon inquiring, I was told that this particular batch of daiginjo was to be made with 100 percent Yamada Nishiki. However, when the day came to start the batch, the rice was not there. “Well, why not just hold off a week or two to start that batch,” one might ask. Unfortunately, it is not that simple. To delay things would push into disarray the whole flow of the subsequent batches, the timing of the steps of which are put together like a jigsaw puzzle. It could also push the brewing of that particular batch late enough into the season that the higher ambient temperatures would have their say in things as well. Et cetera. Ad infinitum. Ad nauseum. So, no; it is not that simple.

But only six percent? Why? Enquiring minds want to know! And so I enquired. And the answer was simple enough: the moto; i.e. the yeast starter.

In other words, the very first step of making a tank of sake, as readers likely remember, is the yeast starter, called the moto (or shubo). The amount of rice that goes into this mini starter batch is about six percent of the final total. And it takes two weeks to make.

So they had a situation in which the Yamada Nishiki rice they wanted was not in, but they had to get started. So they made the yeast starter with what they did have, a perfectly respectable sake rice called Gohyakumangoku, and two weeks later when the Yamada Nishiki they had ordered came in, they continued on with that. Final tally: Gohyakumangoku 6 percent, Yamada Nishiki 94 percent. And being the up-and-up scrupulous brewer that they are, they duly represented it properly on the label.

So they had a situation in which the Yamada Nishiki rice they wanted was not in, but they had to get started. So they made the yeast starter with what they did have, a perfectly respectable sake rice called Gohyakumangoku, and two weeks later when the Yamada Nishiki they had ordered came in, they continued on with that. Final tally: Gohyakumangoku 6 percent, Yamada Nishiki 94 percent. And being the up-and-up scrupulous brewer that they are, they duly represented it properly on the label.

In the decade since these rules were put into place, this was the first time I had come across an actual example. So I do not think most folks will need to worry about it. But should you come across a listing of multiple rice types, the ratios of which seem curious, consider the rice supply story behind it. Just don’t consider it for too long.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Sake Tours! Visit Sake Breweries in Japan! Sake Tours!

Sake. Rice. Swords. Pottery. Hot springs. Gotta admit, Okayama Sake Tour WILL BE best ever. Can’t wait. ow.ly/rxm8S

Sake. Rice. Swords. Pottery. Hot springs. Gotta admit, Okayama Sake Tour WILL BE best ever. Can’t wait. ow.ly/rxm8S

January 27 to 31, 2014

Learn more here: http://saketours.com/tours/okayama/

and the fact that there is no box, but I love this piece. This ochoko is all I need for sake these days, having supplanted far more expensive pieces.

and the fact that there is no box, but I love this piece. This ochoko is all I need for sake these days, having supplanted far more expensive pieces. in spite of the fact that I have bought four of his or her pieces, one or two per year for three years. Picked up at Okeba, the gallery for local artists at Kumazawa Shuzo, producers of the inimitable sake Tensei.

in spite of the fact that I have bought four of his or her pieces, one or two per year for three years. Picked up at Okeba, the gallery for local artists at Kumazawa Shuzo, producers of the inimitable sake Tensei.