Well, almost…

Every spring – and again every fall – it is tasting season here in Japan. What that means is  that those in the industry get to go out to three to five tastings a week of literally hundreds of sake. It is, without a doubt, way too much of a good thing. It’s really about as much fun as an icepick in the forehead. But it is for sure invaluable experience.

that those in the industry get to go out to three to five tastings a week of literally hundreds of sake. It is, without a doubt, way too much of a good thing. It’s really about as much fun as an icepick in the forehead. But it is for sure invaluable experience.

However, the countless sake available to taste and re-taste and take notes on are not the primary appeal.

What is far more important is what can be learned by talking to the brewers in attendance.

Sure, the brewers in attendance are the same ones as always. At this tasting, you will see so-and-so and whatsisface, but at that tasting you will see whodoyacallit and that other guy. Sometimes so-and-so will be at both tasting A and B, so I will strategically plan the order of tasting so as to maximize efficiency.

Of course it is fun to greet everyone; for some of the brewers from the boonies, it is the only time I see them. But what is more important and valuable is the information I can gather. Now that is where the real education is to be had!

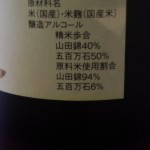

For example, some of the problems plaguing the industry now include rice shortages and proper labeling. The very first booth at which I stopped is a kura with a famous female toji and that is not a million miles away from Iwate. Her labels all said “Domestic rice,” but nothing more about the variety. So naturally, I had to ask her: are you hiding the rice type?

“Nah, of course not. We’re not hiding it. It’s…” and told me a bit about the rice. So, I pressed onward, why don’t you list the rice on the label, then?

“Because,” she continued in a matter-of-fact manner, “with all these rice shortages these days, if we cannot get all of what we ordered, we would be forced to use another rice to finish it off. That would mean we would have to reprint all of our labels to show that. We, as a small company, cannot absorb that hassle, so we avoid it altogether by just writing “domestic” on the label. But we are not hiding it! Just saving ourselves some trouble.”

“Because,” she continued in a matter-of-fact manner, “with all these rice shortages these days, if we cannot get all of what we ordered, we would be forced to use another rice to finish it off. That would mean we would have to reprint all of our labels to show that. We, as a small company, cannot absorb that hassle, so we avoid it altogether by just writing “domestic” on the label. But we are not hiding it! Just saving ourselves some trouble.”

Her decision – and that of others kura doing similar things – has been affected by a handful of mislabeling cases over the last two years. A couple of unscrupulous brewers have gotten busted labeling lower grades of sake as ginjo, or added-alcohol sake as junmai-shu. Some said it was an accident; at least one admitted to the wrongdoing.

In truth, it is but a few bad eggs doing that. But the potential loss of trust of an already-hurting industry, not to mention the potential loss of reputation for a good brewery, have made many companies extremely careful about anything that goes on the label. Not impossible to understand, actually.

Another brewer I know well was all smiles. “This year, we got all the rice we ordered, and  it dissolved properly for us. All is well in my sake-world this year! Rice shortages are passed on to brewers by the distributors providing less than what was fully ordered ten months previous to harvest. It is the only fair way to handle it – decrease all orders across the board, evenly distributing the pain. But this year, this kura at least got it all.

it dissolved properly for us. All is well in my sake-world this year! Rice shortages are passed on to brewers by the distributors providing less than what was fully ordered ten months previous to harvest. It is the only fair way to handle it – decrease all orders across the board, evenly distributing the pain. But this year, this kura at least got it all.

When the weather is too hot, the rice is too hard and will not dissolve in the tank, which means tight and restrained flavors. But this year, it behaved for him, and the sake flavors were full and expressive.

Yet another brewer that is geographically close to the one above was less ebullient. In fact, we was all gripes.

“Yeah, what we got fermented OK, but we did not get all we ordered. And this rice shortage is not about to end. We have the land, and the government regulations have changed to let us grow more, but we do not have enough seeds, and those farmers that grow it are graying fast – no young people want to get into rice farming now.”

Because the seeds must remain pure and can easily be affected by the rice growing nearby, or by what was growing in the same field the previous year, the seeds must come from the agricultural co-op if they are to be inspected. And if the rice is not inspected, rice cannot be labeled as premium. A racket? Sure, to some degree. But not one without its merits or its logic.

He also explained (but asked me to keep it quiet, which is why I am not mentioning the prefecture name) that the whole prefecture lost ten percent of their sake rice since some dork farmer accidentally mixed two rice types before inspection. That means the brewers cannot legally put the name of the rice on the bottle, and if they have two types mixed up in there, it will not likely behave in any way they have yet experienced. So for all intents and purposes, it was lost, further affecting their shortages.

I also found out, much to my surprise, that the powers that be can in fact analyze the DNA of a rice, to be sure that it is what a brewer says it is.

There were lots of other interesting things as well, beyond rice woes.

I continued to run into new rice types, like Tomo no Kaori from Toyama, and new yeasts such as Yuko no Omoi from Iwate that seemed fairly subdued, rather than bold, which was a very refreshing change (the concept, not the sake; although that was refreshing too). I found many more breweries using kensanmai, or rice sourced within the prefecture. While this is likely a result of attempts to ensure supply, it is also a great thing for many other reasons, and seems to be a fairly positive nascent trend.

Then there were a couple of technical things as well. One brewer, Gassan, had a whole new lineup in terms of flavors and style. The reason, interestingly, was that they changed their water source. The water from their own well is extremely soft water, and does not ferment very vigorously. So for decades they have been blending that with hard water brought in from a nearby source. And their sake has long been very enjoyable.

But they decided to bring it all back home, and from this season all of their sake is made with their own water, and in such a way that makes the most of the soft water. So, yeah, the entire lineup is new. It has led to a fascinating change.

There was much more, a lot of it fairly technical and isolated to the respective breweries.

Kikizake-joko – Official Tasting Glasses

And I tasted some good sake too! But walking around and chatting as we tasted was, as usual, even more interesting than the actual sake itself. And I can’t wait until the fall, where there will more of what is already too much of a good thing.

Check out my new book, Sake Confidential!

http://www.cbsdsmarttools.com/sites/m98110/index.html

Japan Sake Awards” was held. While I feel that the “National New Sake Tasting Competition” is much more accurately descriptive, nobody asked me. But I digress.

Japan Sake Awards” was held. While I feel that the “National New Sake Tasting Competition” is much more accurately descriptive, nobody asked me. But I digress.