Suffering does not (always) equal better sake

Sake sadists. They’re out there. You may be one of them. In truth, “sake romanticists” might be just as applicable a term, although it garners less attention. “Sake sadists” makes a better eye-grabbing headline.

To what does that refer? There are many people out there – inside Japan and out, Japanese and not, some that know their sake well and some that do not – that seem to like a sake better if they are led to believe that the brewing staff suffered more when brewing it.

Let’s sake that two glasses of sake were put before someone of this bent. And let us say that for the one on the right, he or she was told that, in order to make this level of quality, the koji was made in such a labor intensive way, and with so much more attention to detail, that the toji (master brewer) had to get up every 90 minutes to check on the moisture and temperature, every day for five months of the year. (Such sake exist!) And let us tell him or her that the one on the left was made using modern equipment that accomplished the same thing, without the koji-person needing to even get out of bed.

Let’s sake that two glasses of sake were put before someone of this bent. And let us say that for the one on the right, he or she was told that, in order to make this level of quality, the koji was made in such a labor intensive way, and with so much more attention to detail, that the toji (master brewer) had to get up every 90 minutes to check on the moisture and temperature, every day for five months of the year. (Such sake exist!) And let us tell him or her that the one on the left was made using modern equipment that accomplished the same thing, without the koji-person needing to even get out of bed.

I can all but guarantee that if these two sake were placed before a sake sadist, he or she would like the one on the right. Deprival. Discomfort. Fatigue. Angst. These are sometimes mistakenly considered to be connected to craftsmanship and quality.

And in truth, sometimes they are. Very commonly the old ways do, in fact, lead to better sake. That is why they have been doing it that way for centuries upon centuries. But not always. Sometimes the ease and comfort that modern technology affords is, actually, just as good as the labor intensive ways, or even better.

Sometimes technology can in fact augment craftsmanship. Not replace it, mind you, but seriously augment it.

An example of this arose when visiting a brewery in Shimane (Ok, it was Rihaku) with a handful of visitors from the US. The president and toji-for-now was explaining how they made their koji. Let me preface this by saying that the company is now transitioning from having an old, experienced toji who could make do with a minimum of modern conveniences like thermometers and scales, and who still cranked out consistently great sake, to young staff that are far less experienced.

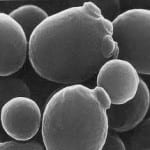

He led a dozen of us into his koji-making room. Therein, steamed rice with a mold sprinkled on it would spend 48 hours or so of pampering and tweaking, permitting the mold to grow into the rice, giving off the enzymes that will liquefy the rice, and convert its starch to sugar. Koji making: the heart of the sake brewing process.

He led a dozen of us into his koji-making room. Therein, steamed rice with a mold sprinkled on it would spend 48 hours or so of pampering and tweaking, permitting the mold to grow into the rice, giving off the enzymes that will liquefy the rice, and convert its starch to sugar. Koji making: the heart of the sake brewing process.

He tapped the thigh-high stainless steel table with the heel of his palm as he spoke. “This entire table sits on a scale. We can see the weight of the rice that sits upon it,” he explained as he pointed to a red LED display in the corner.

“Moisture content is everything in completed koji. It guides the mold, and also affects how fast things dissolve. And we know for each batch of koji precisely what we want that moisture content to be.

“And, because we know how much dry rice we started with, once we load it up here and weigh it we know what the moisture content is at that point. Naturally, that means we know how much moisture we need the rice to give up through evaporation.”

He continued, obviously pleased with his new toy.

“By spreading the rice out over a larger and larger area of the table, we can create more surface area, and blow off less or more moisture, as needed. We adjust that moisture content during the first 24 hours of the koji-making process.”

“By spreading the rice out over a larger and larger area of the table, we can create more surface area, and blow off less or more moisture, as needed. We adjust that moisture content during the first 24 hours of the koji-making process.”

He walked over to the corner of the table, and showed us what is basically a ruler along the edge of the table that indicates the distance from the edge. He then showed us a large, laminated card with a graph printed on it.

“Like I said, we know what we want the moisture to be when our koji is completed. And we know what the moisture content is when the rice comes into this room. So we know how much we need it to give off. And, finally, for a given thickness of the layer of rice sitting on this table, we know how much it will blow off, the speed at which it will dry out.

“So by looking at this graph, we can see that if the rice on the table weighs X kilos, then we spread the rice out on the table as far as point Y. If that is done properly, the perfect amount of moisture will evaporate, and we will have perfect moisture in the rice as we go into the crucial second day of koji making.

“If we set it up this way, with just one experienced person in here, heck, even you guys could make good sake.” This was immediately followed by a surely unintentionally condescending snort.

“But,” he continued, “consumers these days do not want to hear that. No one wants to hear how modern technology and clever ideas makes  sake brewing easier. They want to hear how much effort and angst and hard work we had to do. They want to hear how we suffered to achieve that attention to detail.” He smiled wryly as he slowly shook his head.

sake brewing easier. They want to hear how much effort and angst and hard work we had to do. They want to hear how we suffered to achieve that attention to detail.” He smiled wryly as he slowly shook his head.

“Somehow, people think that the more the brewer had to suffer, the better the sake. Of course, there are steps of the process in which that is close to true. But there are also plenty of clever tricks and modern tools that make sake that is just as good, with less effort.”

He then went on (and on) about how the old toji who had retired a few years ago made do with so much less. He was able to do much of his work without entire tables on scales or graphs. He was so experienced in his craft that he was able to do almost everything by observation, experience and intuition honed through years of dedication to his craft.

Surely there are still toji like that. But not many. As the industry changes, and the brewing staff at more and more kura change from old gnarly guys from the boonies to local youths enjoying a newfound passion, impossibly accurate intuition and modern tools will continue to coexist.

And it will therefore become increasingly important to rein in “sake sadism” and even “sake romanticism”. As long as it tastes and smells good to us, it matters not how it got there.

From Monday, April 3 until Wednesday April 5, I will hold the first Sake Professional Course of 2017 at Bentley Reserve in San Francisco. If interested, for more information please send me an email at sakeguy@gol.com. “No sake stone remains left unturned” in this very comprehensive course. Learn more

From Monday, April 3 until Wednesday April 5, I will hold the first Sake Professional Course of 2017 at Bentley Reserve in San Francisco. If interested, for more information please send me an email at sakeguy@gol.com. “No sake stone remains left unturned” in this very comprehensive course. Learn more  Several years ago, in July of 2014, the Yamagata Prefecture Sake Brewers’ Association began the process of securing a designation of their sake as a Geographical Indication recognized by the World Trade Organization and various international treaties. In order to qualify for something like this, a product (any product applying for a GI) must possess qualities or a reputation that are due to that origin. Securing such a designation gives the region and its producers the exclusive right to an appropriate indication on the label.

Several years ago, in July of 2014, the Yamagata Prefecture Sake Brewers’ Association began the process of securing a designation of their sake as a Geographical Indication recognized by the World Trade Organization and various international treaties. In order to qualify for something like this, a product (any product applying for a GI) must possess qualities or a reputation that are due to that origin. Securing such a designation gives the region and its producers the exclusive right to an appropriate indication on the label. public hearing on the topic on October 19 of this year. It was not made clear how long this stage will take, but assuming it does pass smoothly, Yamagata Sake will come into existence as a bona fide Geographical Indication (GI) for sake. One more region in Japan, the city of Hakusan in Ishikawa Prefecture, has qualified for a GI for the sake of that region. However, it only applies to the five breweries in city of Hakusan; the rest of the breweries in Ishikawa Prefecture are unaffected. Yamagata Prefecture will be the first entire prefecture to secure this distinction.

public hearing on the topic on October 19 of this year. It was not made clear how long this stage will take, but assuming it does pass smoothly, Yamagata Sake will come into existence as a bona fide Geographical Indication (GI) for sake. One more region in Japan, the city of Hakusan in Ishikawa Prefecture, has qualified for a GI for the sake of that region. However, it only applies to the five breweries in city of Hakusan; the rest of the breweries in Ishikawa Prefecture are unaffected. Yamagata Prefecture will be the first entire prefecture to secure this distinction. There are at present 51 sakagura brewing in Yamagata. The oldest of these dates back to the Japanese “Warring States” era of long civil war, while the youngest can trace their roots to the beginning of the Edo period. Even the new kid in town is an old and dignified character.

There are at present 51 sakagura brewing in Yamagata. The oldest of these dates back to the Japanese “Warring States” era of long civil war, while the youngest can trace their roots to the beginning of the Edo period. Even the new kid in town is an old and dignified character. Sake is, as we all know, brewed from rice. Rice, in turn, is a very focused expression of soil, climate, and each year’s weather conditions such as sunshine, rain and typhoons. Every growing season is different, and there are good years for sake rice and bad years for sake rice.

Sake is, as we all know, brewed from rice. Rice, in turn, is a very focused expression of soil, climate, and each year’s weather conditions such as sunshine, rain and typhoons. Every growing season is different, and there are good years for sake rice and bad years for sake rice. Then, it waxes technical. It explains in excruciating detail how higher averages temperatures lead to longer Amylopectin (one of the two components of starch) chains. This means that the starches will dissolve very easily in the moromi (fermenting mash), which means more flavorful sake if controlled, but big-assed sloppy flavors if not reined in. It also accordingly means that resulting sake will be more susceptible to aging the adverse effects of aging.

Then, it waxes technical. It explains in excruciating detail how higher averages temperatures lead to longer Amylopectin (one of the two components of starch) chains. This means that the starches will dissolve very easily in the moromi (fermenting mash), which means more flavorful sake if controlled, but big-assed sloppy flavors if not reined in. It also accordingly means that resulting sake will be more susceptible to aging the adverse effects of aging. Summer in Japan this year was again hot, just about as hot as last year was. The warmer temperatures of the past decade and then some have continued. Furthermore, the islands of Japan were pummeled with typhoons this fall, meaning lots and lots of rain. Factoring in all that and more, the prognosis was that this year’s rice will be not dissolve very well; not too bad, mind you. Just not so well.

Summer in Japan this year was again hot, just about as hot as last year was. The warmer temperatures of the past decade and then some have continued. Furthermore, the islands of Japan were pummeled with typhoons this fall, meaning lots and lots of rain. Factoring in all that and more, the prognosis was that this year’s rice will be not dissolve very well; not too bad, mind you. Just not so well. That’s the cool thing about sake: in making it, we can meet nature half-way. What will most noticeably suffer are the highest grades of sake, contest sake especially. But for most of us, what we will be drinking will be as good as it usually is; but we should not forget that added burden that will be on rice farmers and brewers to make it that way. Sake, like wine, remains an integral expression of nature.

That’s the cool thing about sake: in making it, we can meet nature half-way. What will most noticeably suffer are the highest grades of sake, contest sake especially. But for most of us, what we will be drinking will be as good as it usually is; but we should not forget that added burden that will be on rice farmers and brewers to make it that way. Sake, like wine, remains an integral expression of nature.

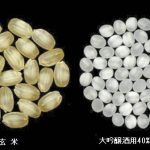

The main raw materials of sake are rice and water, and rice is the only fermentable material used in its production. And just as the grapes used to make good wine are significantly different from those bought at the supermarket, the rice used to make premium sake is significantly different from that which we find sitting under the fish in sushi, or in bowls in meals.

The main raw materials of sake are rice and water, and rice is the only fermentable material used in its production. And just as the grapes used to make good wine are significantly different from those bought at the supermarket, the rice used to make premium sake is significantly different from that which we find sitting under the fish in sushi, or in bowls in meals. Why does sake rice have the starch in the center, and fat and protein around that? Part of it is just the nature of those strains. But it also has to do with climate and growing conditions. Regions with hot days and cold nights are best for sake rice production, as the cold nights coerce the plant to send the starch to the center of the grains. In “bad years” for rice, seasons being too hot or too cold, too wet or too dry, or when the night and day temperatures had less variance, fewer grains will have a decent shinpaku.

Why does sake rice have the starch in the center, and fat and protein around that? Part of it is just the nature of those strains. But it also has to do with climate and growing conditions. Regions with hot days and cold nights are best for sake rice production, as the cold nights coerce the plant to send the starch to the center of the grains. In “bad years” for rice, seasons being too hot or too cold, too wet or too dry, or when the night and day temperatures had less variance, fewer grains will have a decent shinpaku. Note, too, that one can make decent-to-good sake from regular rice. It takes a good toji and good tools, but just a few of the many examples of table rice from which decent sake is brewed are Koshihikari, Sasanishiki, the illustrious Kame no O. So one can indeed make decent sake from table rice. It’s just easier to do so with real sake rice.

Note, too, that one can make decent-to-good sake from regular rice. It takes a good toji and good tools, but just a few of the many examples of table rice from which decent sake is brewed are Koshihikari, Sasanishiki, the illustrious Kame no O. So one can indeed make decent sake from table rice. It’s just easier to do so with real sake rice. The course will be held from the morning of Tuesday, January 10 to the evening of Saturday, January 14,2017, and will be focused in Tokyo, but with a two- day excursion to the Osaka – Kyoto – Kobe area to visit four sake breweries of various scale. Geared toward professionals, but open to anyone with an interest in sake, this course will begin with the basics, and will provide the environment for a focused, intense, and concerted training period. It will consist of classroom sessions on all things sake-related, followed by relevant tasting sessions, four sake brewery visits, and exposure to countless brands and styles in several settings, both in comparison to other sake, and with food. Participants will stay together at hotels in Tokyo and Osaka. Lectures will take place in a comfortable classroom, and evening meals will be off-site at various sake- related establishments.

The course will be held from the morning of Tuesday, January 10 to the evening of Saturday, January 14,2017, and will be focused in Tokyo, but with a two- day excursion to the Osaka – Kyoto – Kobe area to visit four sake breweries of various scale. Geared toward professionals, but open to anyone with an interest in sake, this course will begin with the basics, and will provide the environment for a focused, intense, and concerted training period. It will consist of classroom sessions on all things sake-related, followed by relevant tasting sessions, four sake brewery visits, and exposure to countless brands and styles in several settings, both in comparison to other sake, and with food. Participants will stay together at hotels in Tokyo and Osaka. Lectures will take place in a comfortable classroom, and evening meals will be off-site at various sake- related establishments. The cost for this five-day educational experience is ¥190,000. This includes all instruction and materials, as well as evening meals with plenty of sake each night. Other meals, transportation to and from as well as within Japan, and hotel are not included in the tuition. To make a reservation or if you have any questions at all, please send an email to John Gauntner at sakeguy@gol.com .

The cost for this five-day educational experience is ¥190,000. This includes all instruction and materials, as well as evening meals with plenty of sake each night. Other meals, transportation to and from as well as within Japan, and hotel are not included in the tuition. To make a reservation or if you have any questions at all, please send an email to John Gauntner at sakeguy@gol.com . In the April issue of blog, archived

In the April issue of blog, archived  Before launching into its history and roots, let’s quickly review why it is significantly easier to make good sake using Yamada Nishiki. The grains are large, which means more potential for fermentable starch inside. The starches are concentrated in a ball of starch in the middle, and well centered, meaning it is easy to mill the outer fat and protein away, revealing only the starch. And, that protein and fat are at low levels to begin with, lowering the potential for off-flavors.

Before launching into its history and roots, let’s quickly review why it is significantly easier to make good sake using Yamada Nishiki. The grains are large, which means more potential for fermentable starch inside. The starches are concentrated in a ball of starch in the middle, and well centered, meaning it is easy to mill the outer fat and protein away, revealing only the starch. And, that protein and fat are at low levels to begin with, lowering the potential for off-flavors. But after that change, tax was due in money based on the amount of land they owned. This means that all of a sudden rice was a commodity, a product to be sold on the marketplace that would lead to revenue to pay such taxes and cover living expenses and savings. As such, the more one grew the more one made, and farmers were all of a sudden very motivated to maximize yields and to do that by growing high-yield rice varieties. Sake rice varieties are decidedly not that kind of rice. So, even though demand for rice was increasing, the production of sake rice with its low yields began do prodigiously drop.

But after that change, tax was due in money based on the amount of land they owned. This means that all of a sudden rice was a commodity, a product to be sold on the marketplace that would lead to revenue to pay such taxes and cover living expenses and savings. As such, the more one grew the more one made, and farmers were all of a sudden very motivated to maximize yields and to do that by growing high-yield rice varieties. Sake rice varieties are decidedly not that kind of rice. So, even though demand for rice was increasing, the production of sake rice with its low yields began do prodigiously drop. More information about the course, the schedule, the syllabus and the fun is available

More information about the course, the schedule, the syllabus and the fun is available  York

York While it focuses on the paths of the three of us, a couple-few more people make appearances, including Haruo Matsuzaki, the “sake palate from you-know-where” industry consultant, and Daisuke Suzuki of Suzuki Shuzoten, brewers of Iwaki Kotobuki, who had to leave their kura in Fukushima due all that happened on March 11, 2011, are are now located in Yamagata.

While it focuses on the paths of the three of us, a couple-few more people make appearances, including Haruo Matsuzaki, the “sake palate from you-know-where” industry consultant, and Daisuke Suzuki of Suzuki Shuzoten, brewers of Iwaki Kotobuki, who had to leave their kura in Fukushima due all that happened on March 11, 2011, are are now located in Yamagata.