Again: More Milling is NOT unequivocally better!

In last month’s issue of this newsletter, we pointed out how the rice milling wars are essentially over. In other words, the race to have the most highly milled rice has been won, with one brewer in Miyagi (brewers of Atagonomatsu sake) making a sake with a 0 percent milling rate. This is possible since the number representing the seimai-buai (a number which indicates what remains after milling) is rounded down, so that 0.9 percent can be expressed as 0 percent. This piece of technical one-upmanship took them beyond a kura in Yamagata (brewers of Tatenokawa sake) and their one percent seimai-buai sake.

In last month’s issue of this newsletter, we pointed out how the rice milling wars are essentially over. In other words, the race to have the most highly milled rice has been won, with one brewer in Miyagi (brewers of Atagonomatsu sake) making a sake with a 0 percent milling rate. This is possible since the number representing the seimai-buai (a number which indicates what remains after milling) is rounded down, so that 0.9 percent can be expressed as 0 percent. This piece of technical one-upmanship took them beyond a kura in Yamagata (brewers of Tatenokawa sake) and their one percent seimai-buai sake.

So that has been done. But more significantly, based on the “more milling is better” concept – which has its merits to a certain degree – the drive to make, seek and drink only sake made with highly milled rice has pretty much hit its limit.

In other words, even though milling to 50 percent is enough for a sake to qualify for the technically highest grades of daiginjo and junmai daiginjo, in pursuit of quality – and perhaps a bit of healthy competition – brewers began to push that limit and we have seen sake made with rice milled to 35, 23, 18, 8, 7, as well as the aforementioned one and zero percent sake. Obviously, that is as far as it will go.

However, in all truth, many people pay far too much attention to the seimai-buai number. Yes, it does determine much about the way a

Sake rice: note the opaque center where the starch is concentrated.

sake will taste and smell. And yes, the various grades of sake are defined most significantly by the seimai-buai. So it is of course important. But while the seimai-buai does in fact define much about the final nature and quality of a sake, it is not entirely accurate to say that one milling rate is unequivocally better than another. Not by any stretch of the imagination, does it.

This tendency to place over importance on that number is certainly a bigger issue in Japan than it is overseas – much to the dismay of sake brewers. This is because distributors and restaurants often determine the maximum they are willing to pay based largely on the seimai-buai. They often do not take into account the basic flavor and aromatic profiles, their quality or appeal, or the myriad of other factors above and beyond the milling that went into make a sake as good as it is. But that rabbit-hole discussion is for another day.

So more milling is not necessarily better. And there are a handful of angles from which this can be assessed.

For example, there are various milling techniques that affect the significance of the final seimai-buai number. One is called “flat milling,” or henpei seimai. When this method is used, rice is milled down in such a way that it maintains its original shape, that of a squashed rugby ball, rather than becoming round. Since the starch packet in the center (called the “shimpaku”) has that same almost-oblong shape, henpei seimai milling removes more fat from the sides of the rice, where fat and protein are more accumulated, and less from the ends.

What this really means for us is that for a given seimai-buai number, if the milling was done by henpei seimai, the resulting rice will have a lower fat/protein to starch ratio, i.e. henpei seimai removes a larger proportion of fat and protein than regular milling. So milling to 50 percent using the henpei seimai method might be equivalent to a 40 done by a normal machine.

So why doesn’t everyone use henpei seimai? Because it’s a pain-in-the-butt, that’s why. There are other variations too that accomplish the same goal, that of making rice more suitable for brewing with less actual milling.

Yet another reason more milling is not necessarily advantageous is that once you’ve milled away all that fat and protein, your just diggin’ into the starch packet. Sure, there will always be a bit of fat and protein remaining but with more and more milling one can come closer and closer to eliminating it entirely. But at a certain point it loses touch with brewing reality and ceases to make a difference in the final product.

Yet another reason more milling is not necessarily advantageous is that once you’ve milled away all that fat and protein, your just diggin’ into the starch packet. Sure, there will always be a bit of fat and protein remaining but with more and more milling one can come closer and closer to eliminating it entirely. But at a certain point it loses touch with brewing reality and ceases to make a difference in the final product.

Of course, to be sure, more milling does in fact lead to lighter and more refined flavor profiles. And if light and refined sake is your preference, then you’re golden. More milling is your thing.

But in truth, elegant-and-refined is only one figure of merit in sake. Only one. There are so many more to which to pay attention. For example: Breadth. Depth. Reverb. Resonance. Umami. Richness. Weight. Intensity. These are all wonderful aspects of great sake, and often more milling means less of these. If you like sake with these particular qualities, you will find them more often in sake made with less highly milled rice.

Also, beyond the question of milling, there are a multitude of things to consider in a given sake. For example, what rice was used? What

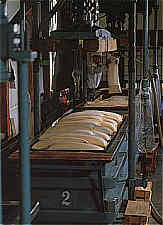

Precision Soaking

grade of that rice and from what region? What year was it brewed, how was it stored, what about pasteurization or the lack thereof? What methods of brewing were used? And of course there are so many more. To only base preferences and decisions on the seimai-buai number is to basically ignore so much pertinent information.

Note, though that this is not to diss daiginjo or sake made with very highly milled rice. That is not my intention at all! Such sake are perfectly valid and invariably well made. It is instead a call to not get wowed solely by the bling of a low number.

We hear this all the time: If you like it, it’s a good sake. And for most of us, what we like will change with time as preferences evolve, and so therefore our definition of what make a good sake will change with time as well. You may find yourself moving away from light, fruity ginjo and toward sturdier, tarter sake. Or you may end up hanging out with daiginjo forever. As long as you find it tasty and enjoyable, you are drinking the best available.

So drink what you like. Do not be afraid of low milling rates like a seimai-buai of 60, 70 or even 80 or more from some producers. Nor should one shy away from the ones and zeroes – if you can find them and if they fit into your budget. It’s all good sake if you like the associated style. Just don’t get blinded by the light.

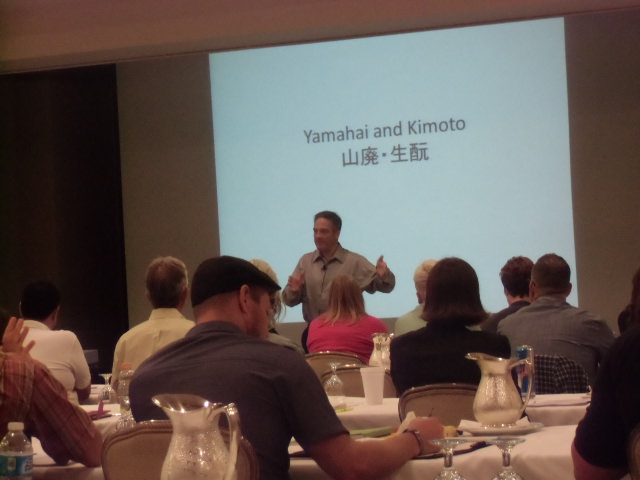

Sake Professional Course, September 25-27, in San Francisco

Currently, only 15 seats remain available. Reserve yours today!

From Wednesday, September 25 to Friday, September 27, 2019, I will hold the 33rd stateside running of the Sake Professional Course in San Francisco. The content of this intensive sake course will be identical to that of the Sake Professional Course held each January in Japan, with the exception of visiting sake breweries. The course is recognized by the Sake Education Council, and those that complete it will be qualified to take the exam for Certified Sake Specialist, which will be offered on the evening of the last day of the course.

From Wednesday, September 25 to Friday, September 27, 2019, I will hold the 33rd stateside running of the Sake Professional Course in San Francisco. The content of this intensive sake course will be identical to that of the Sake Professional Course held each January in Japan, with the exception of visiting sake breweries. The course is recognized by the Sake Education Council, and those that complete it will be qualified to take the exam for Certified Sake Specialist, which will be offered on the evening of the last day of the course.

The course will be followed the next day by the True Sake “Sake Day” event, for which SPC attendees will receive a discount. Learn more here: Sake Professional Course in San Francisco

The last Zenkoku Shinshu Kampyoukai (Officially, the Japan Sake Awards, but more descriptively, the National New Sake Competition) of the Heisei Era was held last month, and the results were recently announced.

The last Zenkoku Shinshu Kampyoukai (Officially, the Japan Sake Awards, but more descriptively, the National New Sake Competition) of the Heisei Era was held last month, and the results were recently announced. upped there industry-leading record to 16 consecutive gold medals in a row. Considering that there are breweries that have never won a single gold medal at all over their entire history, and that winning consecutively is a fairly big accomplishment, that many in a row is quite amazing. Furthermore, the brewery making Urakasumi sake in Miyagi extended their industry leading total to 38, although not consecutively of course.

upped there industry-leading record to 16 consecutive gold medals in a row. Considering that there are breweries that have never won a single gold medal at all over their entire history, and that winning consecutively is a fairly big accomplishment, that many in a row is quite amazing. Furthermore, the brewery making Urakasumi sake in Miyagi extended their industry leading total to 38, although not consecutively of course. So, it’s official. The milling wars are over.

So, it’s official. The milling wars are over. The sake is made by the also aforementioned Niizawa Shuzo in Miyagi, and it redefines “extreme” in sake brewing. The rice was milled for 5297 hours and 34 minutes (that accuracy in reporting is very Japanese!), which is 220 days. That is over seven months of straight milling – compared to three days for most daiginjo, and maybe eight hours for your average junmai-shu. Geezus. The product is called Reikyo, and in English Absolute Zero, and retails for 350,000 yen, or about US$3500 a bottle.

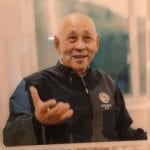

The sake is made by the also aforementioned Niizawa Shuzo in Miyagi, and it redefines “extreme” in sake brewing. The rice was milled for 5297 hours and 34 minutes (that accuracy in reporting is very Japanese!), which is 220 days. That is over seven months of straight milling – compared to three days for most daiginjo, and maybe eight hours for your average junmai-shu. Geezus. The product is called Reikyo, and in English Absolute Zero, and retails for 350,000 yen, or about US$3500 a bottle. Like all worlds, the sake world has its luminaries, its celebrities, and its legendary figures. It would stand to reason that such personages are usually the creators of sake with great reputations; in other words, we would naturally expect that most sake celebrities would be toji, the master brewers behind great brands of sake. However, quite paradoxically, oftentimes the very people that would qualify for such reputations are too humble to claim them. But there have been a few whose presence and reputation loom so large that they end up becoming reluctant legends.

Like all worlds, the sake world has its luminaries, its celebrities, and its legendary figures. It would stand to reason that such personages are usually the creators of sake with great reputations; in other words, we would naturally expect that most sake celebrities would be toji, the master brewers behind great brands of sake. However, quite paradoxically, oftentimes the very people that would qualify for such reputations are too humble to claim them. But there have been a few whose presence and reputation loom so large that they end up becoming reluctant legends. “retirement” to work at nearby Kano Shuzo making the well-known sake Jokigen. This he did for 14 years, until 2012. Do that math: he retired the second time at 79.

“retirement” to work at nearby Kano Shuzo making the well-known sake Jokigen. This he did for 14 years, until 2012. Do that math: he retired the second time at 79. But there he was: quick, dexterous and strong. Together with the young’uns, he was hauling just-steamed rice bundled in cloth, moving with speed and purpose. Later, he was in the koji-making rooms, which are kept between 35C and 45C (!) and at highly humid conditions, working on breaking up rice clumps and spreading and mixing koji mold. It is hard for a normal human being to just be in such an environment, and much harder to actually move and work in one. But there he was, looking as natural and at-home as he could be, exuding the comfort of one who knows just where he truly wants to be.

But there he was: quick, dexterous and strong. Together with the young’uns, he was hauling just-steamed rice bundled in cloth, moving with speed and purpose. Later, he was in the koji-making rooms, which are kept between 35C and 45C (!) and at highly humid conditions, working on breaking up rice clumps and spreading and mixing koji mold. It is hard for a normal human being to just be in such an environment, and much harder to actually move and work in one. But there he was, looking as natural and at-home as he could be, exuding the comfort of one who knows just where he truly wants to be. the nickname “demon.” In fact, his 2003 autobiography was entitled “Demon’s Sake.” So I might not be quite so gushing had I actually had that experience. Still, I am sure the level of respect would be just as high, albeit laced with a few more emotions. But what do I know?

the nickname “demon.” In fact, his 2003 autobiography was entitled “Demon’s Sake.” So I might not be quite so gushing had I actually had that experience. Still, I am sure the level of respect would be just as high, albeit laced with a few more emotions. But what do I know? Mr. Noguchi is not the only great toji out there, nor is he the only famous toji. Far from it! The sake world has its own celebrities, more understated then their western counterparts though they may be. But their presence and aura invigorates the sake world, and makes it all that more interesting for all of us.

Mr. Noguchi is not the only great toji out there, nor is he the only famous toji. Far from it! The sake world has its own celebrities, more understated then their western counterparts though they may be. But their presence and aura invigorates the sake world, and makes it all that more interesting for all of us. Fukushima Prefecture is currently the sake-brewing region garnering the most attention, at least as far as the industry is concerned. Consumers, of course, may not have the same figures of merit as those that brew and assess sake. There are of course many very famous Fukushima sake amongst consumers as well, but when it comes to technical prowess, most consumers could care less. But the industry pays attention to that stuff, and unquestionably, Fukushima rocks.

Fukushima Prefecture is currently the sake-brewing region garnering the most attention, at least as far as the industry is concerned. Consumers, of course, may not have the same figures of merit as those that brew and assess sake. There are of course many very famous Fukushima sake amongst consumers as well, but when it comes to technical prowess, most consumers could care less. But the industry pays attention to that stuff, and unquestionably, Fukushima rocks. beverages as well, at least to some degree. But they are large part of modern sake aromatic and flavor profiles. And in short, isoamyl acetate smells a lot like banana, and ethyl caproate smells a lot like apple, although it can also come across as strawberry, tropical fruit or even anise.

beverages as well, at least to some degree. But they are large part of modern sake aromatic and flavor profiles. And in short, isoamyl acetate smells a lot like banana, and ethyl caproate smells a lot like apple, although it can also come across as strawberry, tropical fruit or even anise. However, in blind tastings on the ginjo and daiginjo level, results tend to favor the above-described formula. And, really, the main point here is that these things can be scientifically categorized, and this gives sake brewers a “strike zone” for which to aim, if brewing such sake is their goal.

However, in blind tastings on the ginjo and daiginjo level, results tend to favor the above-described formula. And, really, the main point here is that these things can be scientifically categorized, and this gives sake brewers a “strike zone” for which to aim, if brewing such sake is their goal.