The two largest sake brewing regions in Japan are also the most accessible!

When work, vacation or other travel brings you to Japan, if you are reading this newsletter, chances are you will be interested in checking out something sake related. If you are here during the brewing season in the winter, many if not most sakagura (breweries) are open to tours, although in almost all cases you would need to call ahead and make reservations and arrangements. So if you or someone you are with speaks the language, this should be no problem.

When work, vacation or other travel brings you to Japan, if you are reading this newsletter, chances are you will be interested in checking out something sake related. If you are here during the brewing season in the winter, many if not most sakagura (breweries) are open to tours, although in almost all cases you would need to call ahead and make reservations and arrangements. So if you or someone you are with speaks the language, this should be no problem.

If you do not have the linguistic wherewithal, though, all is not lost. In Kobe and Kyoto there are several museums attached to sake breweries that have plenty of information in English, and have normal business hours that provide flexibility in allowing guests to drop in almost any time with no reservations.

While museums might not seem like the most sake-intensive experience you can have, these are actually quite informative, interesting and fun. So here is a quick rundown of accessible places to visit in Kobe and Kyoto.

The Nada Region of Kobe

The Hakutsuru Sake Brewery Museum

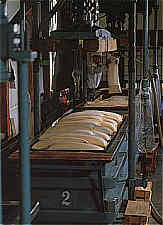

This museum is constructed in one of the old brewery buildings. You need to check in at the main gate. But once that trauma is over, you wander into a beautifully preserved building with a gorgeous garden at the entrance, with the ultra-modern sake brewing plant all around you. Be sure to get an explanatory brochure upon entering (available in several languages). Then, explore the self-guided tour on the first and second floor. There are, at each of perhaps eight stations, television monitors with wonderful two-minute videos showing the major steps in the brewing process, complete with old film footage. Narration is available in either Japanese or English – just select the right button. There are also extremely detailed scenes with manikins and well-preserved traditional old brewing tools that convey quite a realistic feeling of the work load of old. When you are finished, there is a small sake sample of which to partake, along with a video of how to properly taste sake.

This museum is constructed in one of the old brewery buildings. You need to check in at the main gate. But once that trauma is over, you wander into a beautifully preserved building with a gorgeous garden at the entrance, with the ultra-modern sake brewing plant all around you. Be sure to get an explanatory brochure upon entering (available in several languages). Then, explore the self-guided tour on the first and second floor. There are, at each of perhaps eight stations, television monitors with wonderful two-minute videos showing the major steps in the brewing process, complete with old film footage. Narration is available in either Japanese or English – just select the right button. There are also extremely detailed scenes with manikins and well-preserved traditional old brewing tools that convey quite a realistic feeling of the work load of old. When you are finished, there is a small sake sample of which to partake, along with a video of how to properly taste sake.

Also, the gift shop is great, with both great sake and wonderful accoutrements on sale. All in all an excellently informative tour. If you have time for only one place, this would be it.

4-5-5 Sumiyoshi Minami-machi

Higashi Nada-ku, Kobe

TEL: 078-822-8907.

Open daily 9:30 – 4:30, closed Mondays.

Access: Five-minute walk from Hanshin Sumiyoshi Station. Fifteen-minute walk from JR Sumiyoshi Station.

Admission free.

The Kiku Masamune Sake Brewery Museum

The Kiku Masamune Sake Brewery Museum

Perhaps a ten-minute walk away, this museum was destroyed in the Great Hanshin Earthquake that devastated Kobe in 1997, and reopened in January of 1999. The gate and entrance way have been well restored to their original rustic beauty. Be sure to grab one of the lovely brochures (in English or Japanese) at the entrance when you sign in, and look for a detailed map of the breweries in Nada if you do not already have one. In the first large room is an excellent video from 1934 showing black and white brewing scenes, to vintage music. The narration is all in Japanese, but the scenery is easy enough to understand, and the accompanying music is classic. Excellent coverage of large-scale brewing back then, with dozens of men at one time mixing moto (yeast starters) or stirring vats. A small model of a Tarukaisen, the ships that went back and forth between Kobe and Edo, doing nothing but delivering casks of sake, sits near the entrance. Here there are less large brewing implements (although there are some), and more small storage vessels, like bottles and tokkuri and red, lacquered “tsuno-daru.” When you are finished, there are several sake to be sampled in the tasting and retail purchase room.

1-9-1 Uozaki Nishimachi,

Higashi Nada-ku, Kobe

TEL: 078-854-1029.

Open daily 10:00 – 4:00, closed Tuesdays.

Access: Five-minute walk from Hanshin Uozaki Station.Two-minute walk from Rokko Liner Minami Uozaki Station.

Admission free.

Sawa no Tsuru Sake Museum

A short taxi ride away is Sawa no Tsuru’s wonderfully charming museum. Originally constructed in 1978, it was totally destroyed in the Great Hanshin Earthquake. It was reconstructed as a replica of the original, and opened in March 1999. Here, you start with a short film as well, half modern reenactments and half cartoons. But it gets the point across visually. You then follow the flow of the original brewing steps in the old kura. Of particular interest are the reconstruction of the kama (rice steamer) area, and the sunken funaba (sake pressing box) area. Dozens of wooden brewing vats, lined up as they might have been long ago, convey a feeling of what it must have been like. A model of a Tarukaisen is on the second floor. Each of these ships could carry about 1000 koku, or 180 kiloliters, in small casks. That is equivalent to the yearly production of many kura today. When finished, there is a tasting room which offers only one sake for tasting, their genshu honjoz-o, but there are plenty of interesting things like pickles and snacks to purchase.

1-29-1 Oishi Minami-machi

Nada-ku, Kobe

TEL: 078-882-6777

Open daily, 10:00 – 4:00, closed Wednesdays.

Access: Fifteen-minute walk from Hanshin Oishi Station.

Admission free.

Kobe Shushinkan

And then there is Fukuju…

The Kobe Shushinkan brewery was damaged severely in the Great Hanshin Earthquake in 1997, but has done a great job of rising from the ashes. The international award-winning sake brewed by this company is called Fukuju, and it is fairly prominent and lively especially compared to other sake from Nada. Tours are available, but not on a walk-in basis. You can learn a lot more about their brewery and facilities here and you can very easily make a reservation via email here to tour the brewery. It is very worth taking the time and planning ahead, and reaching out to set up a tour.

The Kobe Shushinkan brewery was damaged severely in the Great Hanshin Earthquake in 1997, but has done a great job of rising from the ashes. The international award-winning sake brewed by this company is called Fukuju, and it is fairly prominent and lively especially compared to other sake from Nada. Tours are available, but not on a walk-in basis. You can learn a lot more about their brewery and facilities here and you can very easily make a reservation via email here to tour the brewery. It is very worth taking the time and planning ahead, and reaching out to set up a tour.

Also, they have an extremely cool shop, with sake, sake-related vessels and really interesting trinkets (like coin purses made from old sake filtration bags), and sake-friendly nibbles. Finally, the restaurant Sakabayashi is top notch, although reservations are necessary here too.

Lastly, if you click on the “Sake Breweries” link at the top of the first link mentioned above, you can see a list of all the breweries in Nada that offer tours, as well as a cool sake-centric map of the area.

Kobe Shushinkan

1-8-17 Mikage-tsukamachi, Higashinada-ku, Kobe, Hyogo 658-0044

TEL 078-841-1121

Open Daily 10-6

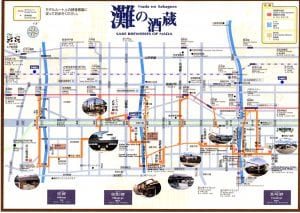

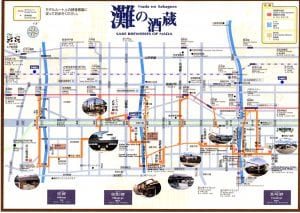

There are several other museums and points of interest in Nada, both museums and restaurants. A very useful map, entitled “Sake Breweries of Nada” and shown at left, can be found here. In fact, a proper search will reveal a whole bunch of maps of Nada sake breweries. And, in fact, a plethora of Nada maps can be found here, the result of a simple search.

There are several other museums and points of interest in Nada, both museums and restaurants. A very useful map, entitled “Sake Breweries of Nada” and shown at left, can be found here. In fact, a proper search will reveal a whole bunch of maps of Nada sake breweries. And, in fact, a plethora of Nada maps can be found here, the result of a simple search.

Fushimi Region of Kyoto

Gekkeikan Okura Memorial Hall

In Fushimi, there are almost 40 sakagura, many in one tight neighborhood worth a walk-through. But perhaps the best museum would be Gekkeikan’s Okura Memorial Hall sake museum. Arguably the most significant brewer across the history of the sake world, many of Gekkeikan’s industry firsts are on display here. There is a partially viewable mini-kura attached, and a restaurant just around the corner. It is in the opposite direction from JR Kyoto station as most of the traditional Kyoto sights, but by no means out of the way. If you go to Kyoto, at least get here.

In Fushimi, there are almost 40 sakagura, many in one tight neighborhood worth a walk-through. But perhaps the best museum would be Gekkeikan’s Okura Memorial Hall sake museum. Arguably the most significant brewer across the history of the sake world, many of Gekkeikan’s industry firsts are on display here. There is a partially viewable mini-kura attached, and a restaurant just around the corner. It is in the opposite direction from JR Kyoto station as most of the traditional Kyoto sights, but by no means out of the way. If you go to Kyoto, at least get here.

Also, right around the corner from this is a sake café that where you can try three sake from each of the breweries in Fushimi. Called the Fushimi Yume Hyakushu, it was the original head office of the company making Gekkeikan.

Gekkeikan Okura Sake Museum (Okura Memorial Hall)

A five minute walk from Chushojima station (Keihan line).

Phone No. 075-623-2056 Admission fee 300 yen (but you get a sake gift upon leaving!)

Open 9:00 – 16:30 Closed Mondays

Kizakura Kappa Country

Kizakura, also in the top five or six sake breweries in the country in terms of production, has amped up their tourist facilities with their Kizakura Kappa Country, with a restaurant, tasting room, and more – of both beer and sake.

It is a new-ish facility but it is in fact their original brewery building. You can see the brewing process here in all its largess, as well as lots of other sake-related stuff. Kizakura has always been a prolific advertiser, unlike most sake breweries, and you can see many of the advertisements they have used over the decades going back into the 50s.

And you can of course try (and buy!) their sake here. Furthermore, they also make good craft beer, and this too is available for sampling and sales at Kappa Country. The sake and beer are both more enjoyable with food, and of course there is a restaurant here as well so that you can confirm that for yourself.

By the way, a kappa is a mythical creature of dubious nature that has long been the corporate symbol for Kizakura. Learn more about kappa here.

Kizakura Kappa Country

228 Shioya-machi, Fushimi-ku, Kyoto City

Tel: 075-611-9919

Opening hours: 10am to 5pm

Closed on Mondays (unless Monday is a national holiday)

There are a few more breweries worth knowing about, and a few more sites to check out in Fushimi, and you can learn a bit about here. Of particular note is the place called Fushim Sakagura Koji, which is a indoor labyrinth of perhaps 20 restaurants and sake bars, at one of which you can order a flifght of 17 (count ‘em!) sake from Fushimi. Also of note is the sake retail shop Aburacho, which sells tons of Fushima sake, and where you can taste almost any sake from Fushimi brewers in the bar in the back. See more on that at the bottom of this guide page.

There are a few more breweries worth knowing about, and a few more sites to check out in Fushimi, and you can learn a bit about here. Of particular note is the place called Fushim Sakagura Koji, which is a indoor labyrinth of perhaps 20 restaurants and sake bars, at one of which you can order a flifght of 17 (count ‘em!) sake from Fushimi. Also of note is the sake retail shop Aburacho, which sells tons of Fushima sake, and where you can taste almost any sake from Fushimi brewers in the bar in the back. See more on that at the bottom of this guide page.

A guide to the sakagura of Fushimi can be found here, within which is a good map of those sakagura, and a veritable plethora of Fushimi maps can be found here.

If you are visiting Japan, even without a fully congealed plan, you simply must avail yourself of visiting at least the most accessible sake related places. Hopefully this guide will get you started. But remember, in many regions around Japan there are breweries open to visits – so be sure to check that out whenever you find yourself in places less accessible than Tokyo, Kobe and Kyoto.

Know more. Appreciate more.

Know more. Appreciate more.

Announcing the launch of a new sake publication, Sake Industry News, a twice-monthly newsletter covering news from within the sake industry in Japan. Learn more and read a few sample issues here.

Sake brewing today has become very scientific. But long ago, before the days of thermometers, hydrometers, and barometers, brewers relied entirely on their five senses to gauge the progress of a fermenting tank of sake. As a curious side note, one toji told me that they compared the accuracy of some of the old school guys to that of modern instruments, and that the old toji of yesteryear were just as accurate as the modern equipment. Not sure this has been scientifically documented, but it is a great anecdote.

Sake brewing today has become very scientific. But long ago, before the days of thermometers, hydrometers, and barometers, brewers relied entirely on their five senses to gauge the progress of a fermenting tank of sake. As a curious side note, one toji told me that they compared the accuracy of some of the old school guys to that of modern instruments, and that the old toji of yesteryear were just as accurate as the modern equipment. Not sure this has been scientifically documented, but it is a great anecdote. of the tank. But soon after this the ferment will enter its most active stage, and foam will rise in great swaths, so that it looks like huge rocks tumbling over each other. This is known as iwa-awa (rock foam).

of the tank. But soon after this the ferment will enter its most active stage, and foam will rise in great swaths, so that it looks like huge rocks tumbling over each other. This is known as iwa-awa (rock foam). After this foam, too, fades away, the surface of the moromi is referred to as ji, or ground. This stage has many sub-conditions with their own names. Small wrinkles in the surface are referred to as chiri-men (a type of rough cloth). A totally smooth surface is known as bozu, in reference to the shaved head of a priest. If rice solids that did not ferment have risen to the surface, it may look like a lid is on the moromi, and this is referred to as futa (lid).

After this foam, too, fades away, the surface of the moromi is referred to as ji, or ground. This stage has many sub-conditions with their own names. Small wrinkles in the surface are referred to as chiri-men (a type of rough cloth). A totally smooth surface is known as bozu, in reference to the shaved head of a priest. If rice solids that did not ferment have risen to the surface, it may look like a lid is on the moromi, and this is referred to as futa (lid). Know more. Appreciate more.

Know more. Appreciate more.

Next, to be doubly certain, he soaked the next basked fifteen seconds longer; it ended up at 33 percent. To wrap it up, he soaked the third basket fifteen seconds shorter; not surprisingly it ended up at 31 percent. He then instructed the other workers to soak the remaining few dozen baskets for nine minutes, exactly, and stepped aside to lead us on a tour of the rest of the kura.

Next, to be doubly certain, he soaked the next basked fifteen seconds longer; it ended up at 33 percent. To wrap it up, he soaked the third basket fifteen seconds shorter; not surprisingly it ended up at 31 percent. He then instructed the other workers to soak the remaining few dozen baskets for nine minutes, exactly, and stepped aside to lead us on a tour of the rest of the kura.

When looking at the history of sake, both culturally and from the point of technical developments, there is a period in the “dark ages” during which sake brewing was done mainly in shrines and temples in Japan. Interestingly, this was a period of huge strides in brewing methods and technology. But unfortunately, this period of sake history tends to get conveyed in a very abbreviated and minimalist form. It usually takes a back seat to issues such as knowing the grades and types, or how sake is brewed.

When looking at the history of sake, both culturally and from the point of technical developments, there is a period in the “dark ages” during which sake brewing was done mainly in shrines and temples in Japan. Interestingly, this was a period of huge strides in brewing methods and technology. But unfortunately, this period of sake history tends to get conveyed in a very abbreviated and minimalist form. It usually takes a back seat to issues such as knowing the grades and types, or how sake is brewed. characterized by the veneration of spirits in nature and nature’s manifestations, as well as ancestors, and is refreshingly free of anything remotely resembling a formal dogma.) There is a Shinto ceremony called O-miki performed with a Shinto priest in a shrine, and using unique white porcelain flasks (called miki-dokkuri) and cups that can be seen on the altars of shrines everywhere. In this ceremony, a small amount of sake is drunk in a prayerful act of symbolic unification with the gods.

characterized by the veneration of spirits in nature and nature’s manifestations, as well as ancestors, and is refreshingly free of anything remotely resembling a formal dogma.) There is a Shinto ceremony called O-miki performed with a Shinto priest in a shrine, and using unique white porcelain flasks (called miki-dokkuri) and cups that can be seen on the altars of shrines everywhere. In this ceremony, a small amount of sake is drunk in a prayerful act of symbolic unification with the gods.

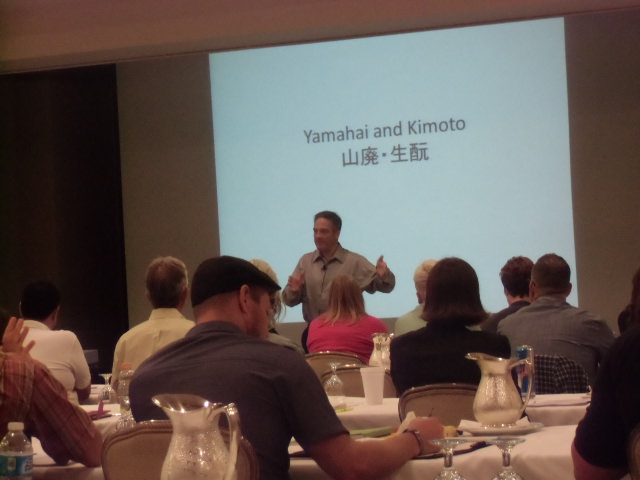

And so it was here that brewing methods were developed that led to much better sake, a definition that includes (as well it should) significantly higher alcohol levels. Most significantly, it was about this time when the rice, koji and water were added to the fermenting mash in two separate doses to help keep the yeast population at levels high enough to defeat bacterial intruders through sheer numbers. (This later evolved into three additions, as it remains today.) A form of yeast starter known as “Bodai-moto” was also developed by these clever clerics, and this is considered to be the roots of the kimoto yeast starter method, widely recognized as the original yeast starter method of modern sake brewing. Other significant technical developments from the Nara Buddhist temples include pasteurization and milling both the koji rice and the regular rice.

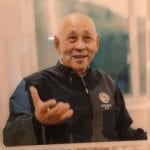

And so it was here that brewing methods were developed that led to much better sake, a definition that includes (as well it should) significantly higher alcohol levels. Most significantly, it was about this time when the rice, koji and water were added to the fermenting mash in two separate doses to help keep the yeast population at levels high enough to defeat bacterial intruders through sheer numbers. (This later evolved into three additions, as it remains today.) A form of yeast starter known as “Bodai-moto” was also developed by these clever clerics, and this is considered to be the roots of the kimoto yeast starter method, widely recognized as the original yeast starter method of modern sake brewing. Other significant technical developments from the Nara Buddhist temples include pasteurization and milling both the koji rice and the regular rice. Like all worlds, the sake world has its luminaries, its celebrities, and its legendary figures. It would stand to reason that such personages are usually the creators of sake with great reputations; in other words, we would naturally expect that most sake celebrities would be toji, the master brewers behind great brands of sake. However, quite paradoxically, oftentimes the very people that would qualify for such reputations are too humble to claim them. But there have been a few whose presence and reputation loom so large that they end up becoming reluctant legends.

Like all worlds, the sake world has its luminaries, its celebrities, and its legendary figures. It would stand to reason that such personages are usually the creators of sake with great reputations; in other words, we would naturally expect that most sake celebrities would be toji, the master brewers behind great brands of sake. However, quite paradoxically, oftentimes the very people that would qualify for such reputations are too humble to claim them. But there have been a few whose presence and reputation loom so large that they end up becoming reluctant legends. “retirement” to work at nearby Kano Shuzo making the well-known sake Jokigen. This he did for 14 years, until 2012. Do that math: he retired the second time at 79.

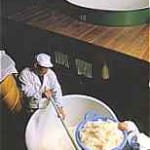

“retirement” to work at nearby Kano Shuzo making the well-known sake Jokigen. This he did for 14 years, until 2012. Do that math: he retired the second time at 79. But there he was: quick, dexterous and strong. Together with the young’uns, he was hauling just-steamed rice bundled in cloth, moving with speed and purpose. Later, he was in the koji-making rooms, which are kept between 35C and 45C (!) and at highly humid conditions, working on breaking up rice clumps and spreading and mixing koji mold. It is hard for a normal human being to just be in such an environment, and much harder to actually move and work in one. But there he was, looking as natural and at-home as he could be, exuding the comfort of one who knows just where he truly wants to be.

But there he was: quick, dexterous and strong. Together with the young’uns, he was hauling just-steamed rice bundled in cloth, moving with speed and purpose. Later, he was in the koji-making rooms, which are kept between 35C and 45C (!) and at highly humid conditions, working on breaking up rice clumps and spreading and mixing koji mold. It is hard for a normal human being to just be in such an environment, and much harder to actually move and work in one. But there he was, looking as natural and at-home as he could be, exuding the comfort of one who knows just where he truly wants to be. the nickname “demon.” In fact, his 2003 autobiography was entitled “Demon’s Sake.” So I might not be quite so gushing had I actually had that experience. Still, I am sure the level of respect would be just as high, albeit laced with a few more emotions. But what do I know?

the nickname “demon.” In fact, his 2003 autobiography was entitled “Demon’s Sake.” So I might not be quite so gushing had I actually had that experience. Still, I am sure the level of respect would be just as high, albeit laced with a few more emotions. But what do I know? Mr. Noguchi is not the only great toji out there, nor is he the only famous toji. Far from it! The sake world has its own celebrities, more understated then their western counterparts though they may be. But their presence and aura invigorates the sake world, and makes it all that more interesting for all of us.

Mr. Noguchi is not the only great toji out there, nor is he the only famous toji. Far from it! The sake world has its own celebrities, more understated then their western counterparts though they may be. But their presence and aura invigorates the sake world, and makes it all that more interesting for all of us.